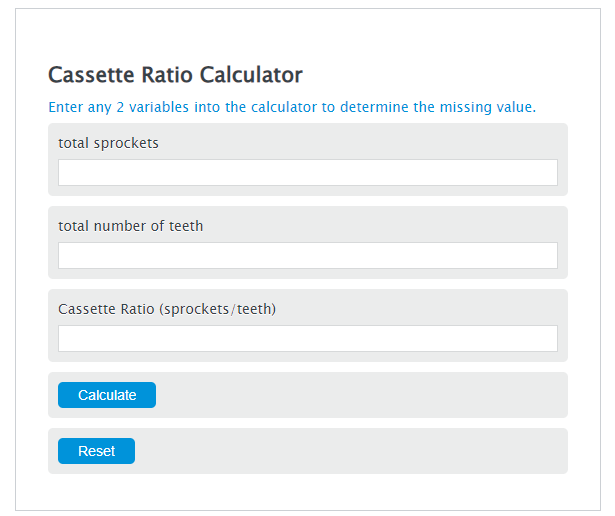

Enter the total sprockets and the total number of teeth into the Calculator. The calculator will evaluate the Cassette Ratio.

Cassette Ratio Formula

CR = S/T

Variables:

- CR is the Cassette Ratio (sprockets/teeth)

- S is the total sprockets

- T is the total number of teeth

To calculate the Cassette Ratio, divide the total sprockets by the total number of teeth.

How to Calculate Cassette Ratio?

The following steps outline how to calculate the Cassette Ratio.

- First, determine the total sprockets.

- Next, determine the total number of teeth.

- Next, gather the formula from above = CR = S/T.

- Finally, calculate the Cassette Ratio.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

total sprockets = 20

total number of teeth = 15

FAQ

What is a Cassette Ratio in mechanical terms?

A Cassette Ratio is a measure used in mechanics to describe the ratio of the total number of sprockets to the total number of teeth on a gear or cog. This ratio is crucial in determining the mechanical advantage and efficiency of gear systems in machines and bicycles.

Why is the Cassette Ratio important for bicycles?

The Cassette Ratio on a bicycle affects how easy or hard it is to pedal. A higher ratio means more pedaling effort is needed but results in higher speed, suitable for flat surfaces. A lower ratio makes it easier to pedal, especially useful for climbing hills.

How does changing the Cassette Ratio affect a machine’s performance?

Adjusting the Cassette Ratio can significantly affect a machine’s speed and torque. A higher ratio increases speed but reduces torque, making the machine faster but less powerful. Conversely, a lower ratio decreases speed but increases torque, enhancing the machine’s ability to perform heavy-duty tasks.

Can the Cassette Ratio affect the longevity of a machine or bicycle?

Yes, an improperly balanced Cassette Ratio can lead to increased wear and tear on the machine or bicycle’s components. An optimal ratio ensures that the system operates efficiently, reducing strain on parts and potentially extending the lifespan of the equipment.