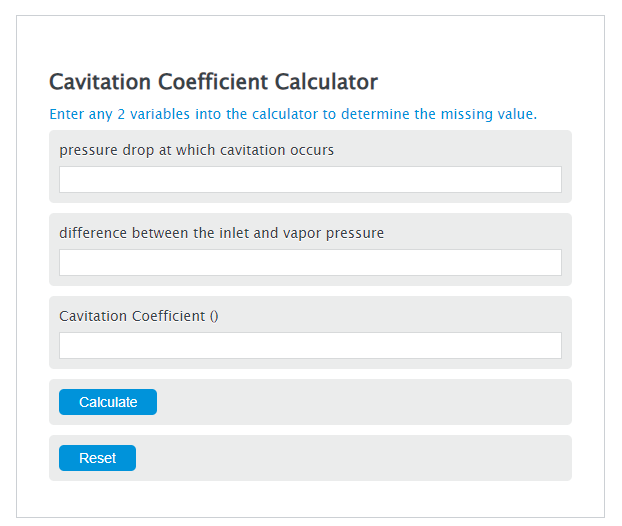

Enter the pressure drop at which cavitation occurs and the difference between the inlet and vapor pressure into the Calculator. The calculator will evaluate the Cavitation Coefficient.

Cavitation Coefficient Formula

CC = PD / (dIV)

Variables:

- CC is the Cavitation Coefficient ()

- PD is the pressure drop at which cavitation occurs

- dIV is the difference between the inlet and vapor pressure

To calculate Cavitation Coefficient, divide the pressure drop at which cavitation occurs by the difference between the inlet and vapor pressures.

How to Calculate Cavitation Coefficient?

The following steps outline how to calculate the Cavitation Coefficient.

- First, determine the pressure drop at which cavitation occurs.

- Next, determine the difference between the inlet and vapor pressure.

- Next, gather the formula from above = CC = PD / (dIV).

- Finally, calculate the Cavitation Coefficient.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

pressure drop at which cavitation occurs = 40

difference between the inlet and vapor pressure = 203

Frequently Asked Questions

What is cavitation and why is it important in fluid dynamics?

Cavitation occurs when the pressure in a liquid suddenly drops below its vapor pressure, leading to the formation of small vapor bubbles. This phenomenon is important in fluid dynamics because it can cause wear and tear on equipment, reduce efficiency, and even lead to failure of hydraulic systems.

How does the Cavitation Coefficient help in predicting cavitation?

The Cavitation Coefficient is a dimensionless number that helps in predicting the likelihood of cavitation occurring in a fluid flow system. It is calculated by dividing the pressure drop at which cavitation occurs by the difference between the inlet and vapor pressure. A lower Cavitation Coefficient indicates a higher risk of cavitation.

Can cavitation be avoided, and if so, how?

Yes, cavitation can often be avoided by ensuring that the fluid pressure throughout the system stays above the vapor pressure. This can be achieved through proper system design, maintaining higher inlet pressures, reducing fluid temperatures (to lower vapor pressure), or by using anti-cavitation valves in hydraulic systems.

Are there any industries or applications where monitoring cavitation is particularly critical?

Monitoring cavitation is critical in industries and applications involving high-speed pumps, turbines, propellers, and hydraulic systems, such as in power generation, water treatment, marine, and aerospace industries. In these settings, cavitation can severely impact the performance and lifespan of equipment.