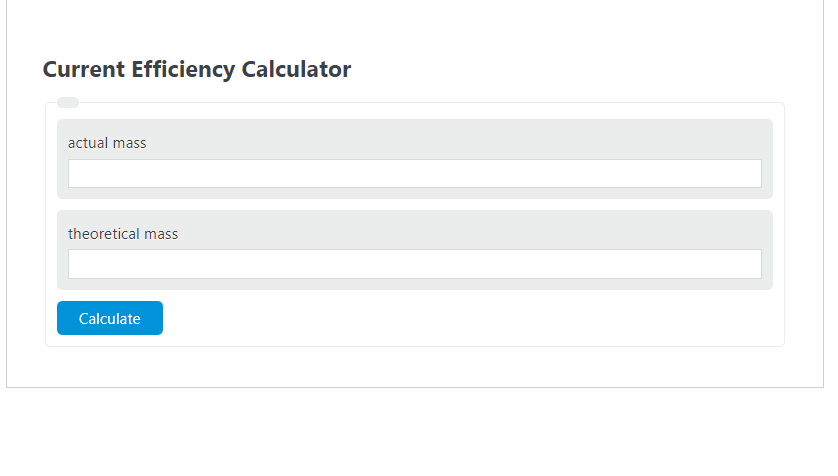

Enter the actual mass and the theoretical mass into the calculator to determine the Current Efficiency.

- All Efficiency Calculators

- Structural Efficiency Calculator

- Quantum Efficiency Calculator

- QPCR Efficiency Calculator

Current Efficiency Formula

The following formula is used to calculate the Current Efficiency.

Ec = AM / TM * 100

- Where Ec is the Current Efficiency (%)

- AM is the actual mass

- TM is the theoretical mass

To calculate the current efficiency, divide the actual mass by the theoretical mass, then multiply by 100.

How to Calculate Current Efficiency?

The following two example problems outline how to calculate the Current Efficiency.

Example Problem #1:

- First, determine the actual mass. In this example, the actual mass is given as 78.

- Next, determine the theoretical mass. For this problem, the theoretical mass is given as 80.

- Finally, calculate the Current Efficiency using the equation above:

Ec = AM / TM * 100

Inserting the values from above and solving the equation:

Ec = 78 / 80 * 100 = 97.5 (%)

FAQ

What is the significance of measuring Current Efficiency?

Measuring Current Efficiency is crucial in various industries, especially in manufacturing and chemical processes, as it helps in assessing the performance and efficiency of production processes. By understanding the actual output compared to the theoretical maximum, companies can identify areas for improvement, optimize resource use, and reduce waste, leading to cost savings and more sustainable operations.

Can Current Efficiency exceed 100%?

No, Current Efficiency cannot exceed 100% as it represents the ratio of the actual output to the theoretical maximum output. A value above 100% would imply that the process is producing more than what is theoretically possible, which contradicts the laws of physics and principles of conservation. If calculations suggest an efficiency over 100%, it usually indicates an error in measurement or an unrealistic theoretical expectation.

How can one improve the Current Efficiency of a process?

Improving Current Efficiency involves optimizing the process to reduce waste and enhance the yield of the desired output. This can be achieved through various means, including refining operational parameters (such as temperature, pressure, and reaction time), improving material quality, employing more efficient technology or equipment, and conducting regular maintenance to prevent performance degradation. Additionally, continuous monitoring and analysis of process data can help identify inefficiencies and areas for improvement.