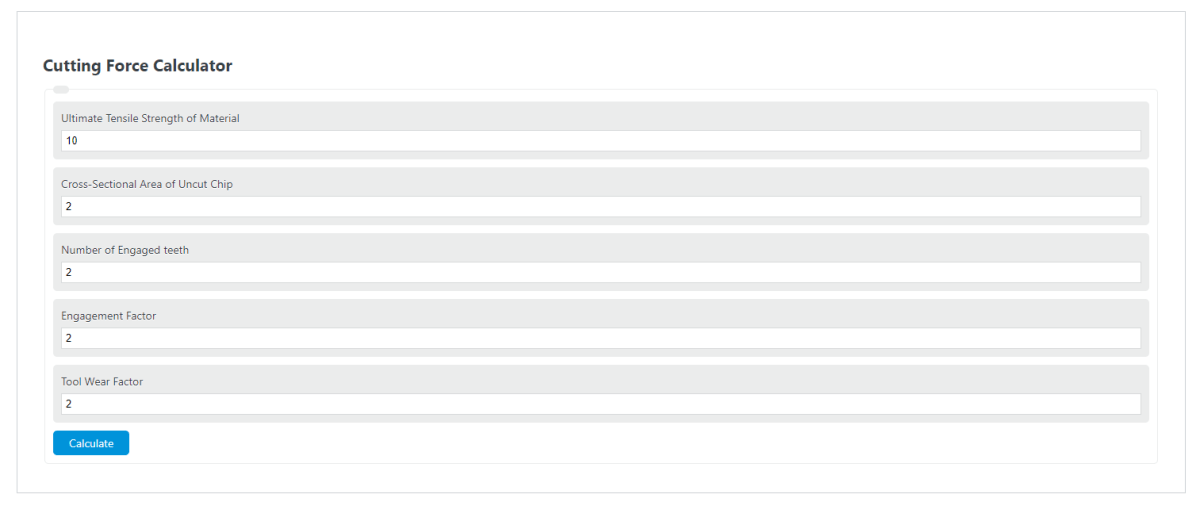

Enter the tensile strength of the material, the cross-sectional area of the uncut chip, the number of teeth engaged with the workpiece, the engagement factor, and the cutting tool wear factor to determine the tangential cutting force.

- All Force Calculators

- Cutting Time Calculator

- Chip Load Calculator

- Material Removal Rate Calculator

- Lathe RPM Calculator

- Press Force Calculator

- Tube Sheet Thickness Calculator

- Drawing Force Calculator

- Stripping Force Calculator

Cutting Force Formula

The following equation is used to calculate the Cutting Force.

Ft = σ *A*Z*E*T

- Where Ft is the tangential cutting force of the milling operation

- σ is the ultimate tensile strength of the material

- A is the cross-sectional area of the uncut chip

- Z is the number of engaged teeth with the workpiece

- E is the engagement factor of the workpiece material

- T is the cutting tool wear factor

To calculate the cutting force, multiply the ultimate tensile strength, cross-sectional area, number of engaged teeth, engagement factor, and cutting tool wear factor together.

What is a Cutting Force?

Definition:

A cutting force is defined as the total tangential force acting on a material during a cutting/milling operation.

How to Calculate Cutting Force?

Example Problem:

The following example outlines the steps and information needed to calculate Cutting Force.

Determine the values for the variables mentioned in the formula above. For this example, these are as follows:

- σ = 4,000

- A = 2.5

- Z = 2

- E = 1.5

- T = .45

Next, use the formula above to calculate the tangential cutting force.

Ft = σ *A*Z*E*T

Ft = 4000*2.5*2*1.5*.45

Ft = 13,500 N

FAQ

What factors influence the tangential cutting force in a milling operation?

The tangential cutting force in a milling operation is influenced by several factors including the ultimate tensile strength of the material being cut, the cross-sectional area of the uncut chip, the number of teeth on the cutting tool that are engaged with the workpiece, the engagement factor of the workpiece material, and the wear factor of the cutting tool.

How does the wear factor of a cutting tool affect the cutting force?

The wear factor of a cutting tool directly affects the cutting force by altering the efficiency and effectiveness of the cutting process. A higher wear factor indicates more wear on the cutting tool, which can lead to increased cutting force as the tool requires more energy to cut through the material. Regularly maintaining and replacing cutting tools can help manage the cutting force required.

Can the cutting force be reduced by changing the cutting conditions?

Yes, the cutting force can be reduced by optimizing cutting conditions such as adjusting the speed and feed rate of the cutting tool, selecting a tool with more suitable material and coating, and using a lubricant to reduce friction. Additionally, optimizing the number of engaged teeth and the cross-sectional area of the uncut chip can also help in reducing the cutting force.