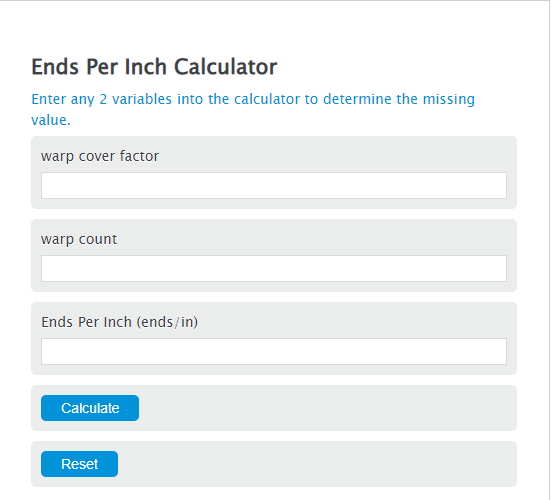

Enter the warp cover factor and the warp count into the Calculator. The calculator will evaluate the Ends Per Inch.

Ends Per Inch Formula

EPI = WCF * SQRT(WC)

Variables:

- EPI is the Ends Per Inch (ends/in)

- WCF is the warp cover factor

- WC is the warp count

To calculate Ends Per Inch, multiply the warp cover factor by the square root of the warp count.

How to Calculate Ends Per Inch?

The following steps outline how to calculate the Ends Per Inch.

- First, determine the warp cover factor.

- Next, determine the warp count.

- Next, gather the formula from above = EPI = WCF * SQRT(WC).

- Finally, calculate the Ends Per Inch.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

warp cover factor = 3.4

warp count = 2

FAQs

What is warp cover factor in textile manufacturing?

Warp cover factor is a numerical value that represents the coverage of warp yarns on the surface of a woven fabric. It is determined by the density and arrangement of warp yarns and is used to calculate the Ends Per Inch (EPI) in the weaving process.

Why is the Ends Per Inch (EPI) important?

EPI is crucial in textile manufacturing because it determines the density of the warp yarns in a fabric. A higher EPI means a denser fabric, which can affect the fabric’s strength, appearance, and end use. It’s essential for ensuring the quality and specifications of the finished textile product.

How does the warp count affect fabric quality?

The warp count, which refers to the thickness or fineness of the warp yarns, significantly impacts the fabric’s overall quality. Finer yarns (higher warp count) can lead to smoother, more detailed fabrics, while thicker yarns (lower warp count) are used for heavier, more durable textiles.

Can the Ends Per Inch be adjusted after weaving?

Once a fabric is woven, adjusting the Ends Per Inch is not feasible without altering the fabric structure significantly. Therefore, accurate calculation and setting of EPI before the weaving process are critical for achieving the desired fabric quality and characteristics.