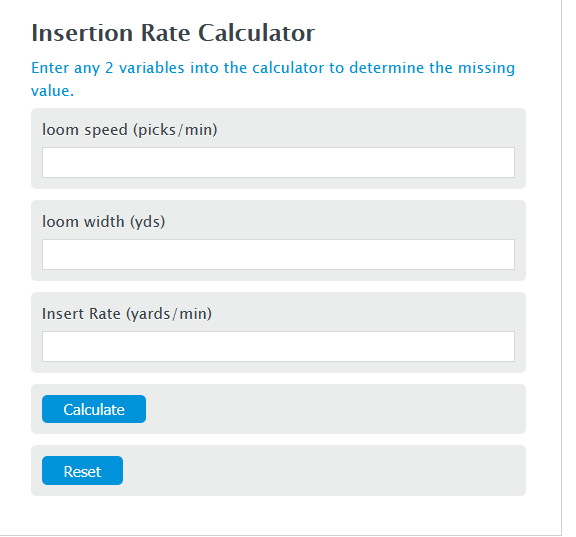

Enter the loom speed (picks/min) and the loom width (yds) into the Calculator. The calculator will evaluate the Insert Rate.

Insert Rate Formula

INSR = LS * LW

Variables:

- INSR is the Insert Rate (yards/min)

- LS is the loom speed (picks/min)

- LW is the loom width (yds)

To calculate Insert Rate, multiply the loom speed by the loom width.

How to Calculate Insert Rate?

The following steps outline how to calculate the Insert Rate.

- First, determine the loom speed (picks/min).

- Next, determine the loom width (yds).

- Next, gather the formula from above = INSR = LS * LW.

- Finally, calculate the Insert Rate.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

loom speed (picks/min) = 45

loom width (yds) = 30

FAQ

What is a loom speed in the context of textile manufacturing?

Loom speed refers to the number of picks (weft threads) inserted across the warp in a minute. It is a crucial factor in determining the weaving efficiency and productivity of a loom.

How does loom width affect the insert rate?

The loom width, measured in yards, directly impacts the insert rate as it determines the breadth of fabric that can be produced in a single operation. A wider loom allows for a greater amount of fabric to be produced per minute, thereby increasing the insert rate.

Why is calculating the insert rate important in the textile industry?

Calculating the insert rate is essential for optimizing production efficiency and cost-effectiveness. It helps manufacturers estimate the output of their looms and make informed decisions about production schedules, resource allocation, and potential investments in new equipment.

Can the insert rate be improved, and if so, how?

Yes, the insert rate can be improved by optimizing loom speed and width, ensuring the loom is well-maintained to minimize downtime, and using higher quality materials that allow for faster weaving. Training operators to better manage the loom can also contribute to improved efficiency.