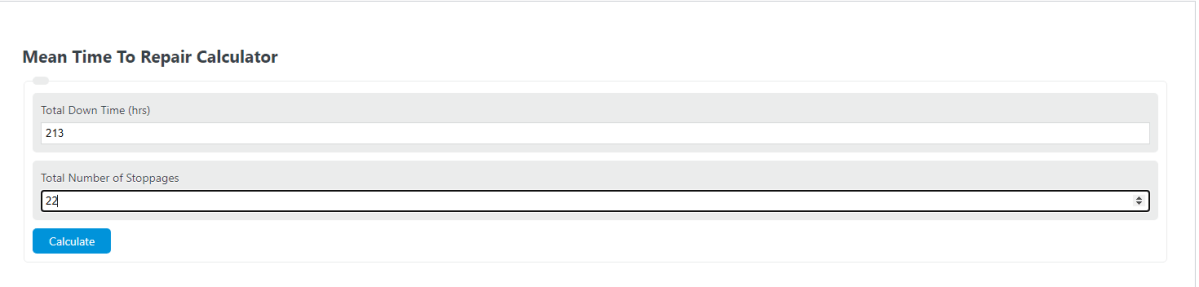

Enter the total number of stoppages and the total downtime into the calculator to determine the mean time to repair (MTR).

- Mean Time To Failure (MTTF) Calculator

- Mean Time Between Failures (MTBF) Calculator

- Failure Rate Calculator

- Overall Equipment Effectiveness (OEE) Calculator

- Injector Duty Cycle Calculator

MTR Formula

The following formula is used to calculate a mean time to repair.

MTR = D / S

- Where MTR is the mean time to repair (hrs/min)

- D is the total downtime (hrs/min)

- #S is the total number of stoppages

To calculate the mean time to repair, divide the total downtime by the number of stoppages.

MTR Definition

What is mttr?

MTTR, also sometimes denoted MTR, which is short for mean time to repair, is a term used to describe the average amount of time it takes for a piece of equipment, typically machinery, to be repaired when it has a technical issue or stoppage.

The mean time to repair is used for calculations such as overall equipment effectiveness, which allows businesses and companies to analyze how well their equipment is performing.

Example Problem

How to calculate the mean time to repair?

The following example problem outlines the information and steps required to calculate an average time to repair.

First, determine a time period that will be analyzed for stoppages and repairs. In this example, the time is a 6-month period.

Next, measure the total number of stoppages during the time period. In this case, there were 4 stoppages measured.

Next, measure the total downtown of the machine over the 6 months. This is found to be 40 hours.

Finally, calculate the mean time to repair (MTR) using the forum above:

MTR = D / #S

MTR = 40 / 4

MTR = 10 hours

FAQ

What factors can affect the Mean Time to Repair (MTR) for machinery?

Various factors can influence the MTR for machinery, including the complexity of the machine, the availability of spare parts, the skill level of the maintenance team, and the initial condition of the equipment. Environmental conditions and how frequently the machinery is used can also play significant roles.

How can improving MTR benefit a business?

Improving MTR can significantly benefit a business by reducing downtime, increasing production efficiency, improving overall equipment effectiveness (OEE), and ultimately leading to higher customer satisfaction and lower operational costs. It can also contribute to a safer working environment by ensuring machinery is properly maintained.

Are there any best practices for reducing the Mean Time to Repair?

Yes, several best practices can help reduce MTR, including implementing a preventive maintenance schedule, training the maintenance team effectively, keeping a well-organized inventory of essential spare parts, employing condition monitoring tools, and adopting a continuous improvement mindset towards maintenance processes.