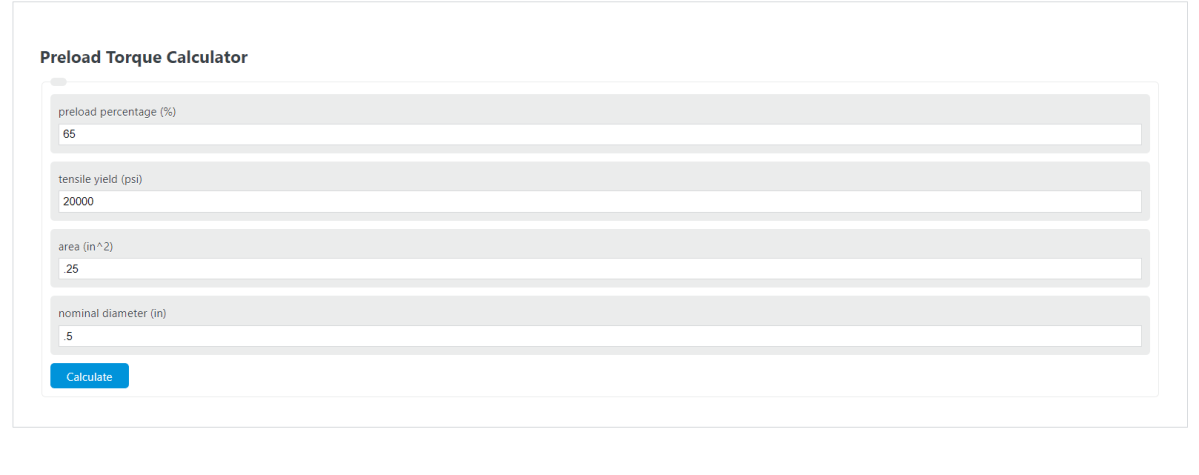

Enter the preload percentage (%), the tensile yield (psi), nominal diameter (in), and the area (in^2) into the calculator to determine the Preload Torque.

- All Torque Calculators

- Bolt Preload Calculator

- Bolt Pull Out Force Calculator

- Flange Bolt Torque Calculator

- Fastener Torque Calculator

Preload Torque Formula

The following formula is used to calculate the Preload Torque.

Tpl = (yp/100*S*A)*d/12

- Where Tpl is the Preload Torque (lbf-ft)

- yp is the preload percentage (%)

- S is the tensile yield (psi)

- A is the area (in^2)

- d is the nominal diameter (in)

To calculate the preload torque, divide the preload percentage by 100, multiply by the tensile yield and area, then multiply by the nominal diameter over 12.

How to Calculate Preload Torque?

The following example problems outline how to calculate Preload Torque.

Example Problem #1

- First, determine the preload percentage (%). In this example, the preload percentage (%) is determined to be 65 .

- Next, determine the tensile yield (psi). For this problem, the tensile yield (psi) is measured to be 20000 .

- Next, determine the area (in^2). In this case, the area (in^2) is found to be .25.

- Next, determine the diameter. For this problem, this is .50 in.

- Finally, calculate the Preload Torque using the formula above:

Tpl = (y%/100*S*A)*d/12

Inserting the values from above and solving yields:

Tpl = (65/100*20,000*.25)*.50/12 = 135.41 (lbf-ft)

FAQ

What factors influence the calculation of preload torque in bolted connections?

The calculation of preload torque in bolted connections is influenced by several factors including the preload percentage, tensile yield strength of the material, the cross-sectional area of the bolt, and the nominal diameter of the bolt. Environmental factors such as temperature and humidity, as well as the presence of lubrication, can also affect the required preload torque.

How does preload torque affect the reliability of bolted joints?

Preload torque directly impacts the reliability and performance of bolted joints. Proper preload helps to ensure that the joint remains secure under operational loads, reducing the risk of bolt loosening due to vibrations or cyclic loads. However, excessive preload can lead to bolt or material failure, while insufficient preload may result in joint separation or slippage.

Can the preload torque formula be applied to all types of bolts and materials?

The preload torque formula provided can be applied as a general guideline for calculating the preload torque for various types of bolts and materials. However, specific factors such as bolt material, thread pitch, and lubrication conditions can affect the actual preload torque required. It is important to consult material specifications and engineering standards for precise calculations, especially in critical applications.