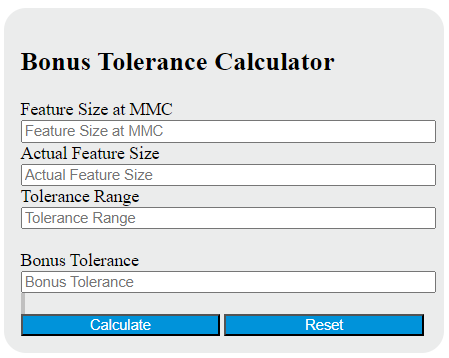

Enter the feature size at maximum material condition, actual feature size, and tolerance range into the calculator to determine the bonus tolerance.

Bonus Tolerance Formula

The following formula is used to calculate the bonus tolerance.

BT = (FV - AV) * TR

Variables:

- BT is the bonus tolerance

- FV is the feature size at maximum material condition (MMC)

- AV is the actual feature size

- TR is the tolerance range

To calculate the bonus tolerance, subtract the actual feature size from the feature size at maximum material condition. Multiply the result by the tolerance range.

What is a Bonus Tolerance?

A bonus tolerance is an additional tolerance given in a geometric dimensioning and tolerancing (GD&T) system that allows for greater manufacturing flexibility. It is typically associated with features like holes or slots that are designed to fit a mating part. The bonus tolerance comes into play when the actual feature size is less than the maximum material condition (MMC), allowing for additional tolerance on geometric controls such as position, profile, orientation, and runout. This can result in cost savings and increased efficiency in the manufacturing process.

How to Calculate Bonus Tolerance?

The following steps outline how to calculate the Bonus Tolerance using the given formula:

- First, determine the feature size at maximum material condition (MMC) (FV).

- Next, determine the actual feature size (AV).

- Next, determine the tolerance range (TR).

- Next, insert the values into the formula: BT = (FV – AV) * TR.

- Finally, calculate the Bonus Tolerance (BT).

- After calculating the result, check your answer for accuracy.

Example Problem:

Use the following variables as an example problem to test your knowledge:

Feature size at maximum material condition (MMC) (FV) = 10

Actual feature size (AV) = 8

Tolerance range (TR) = 0.5