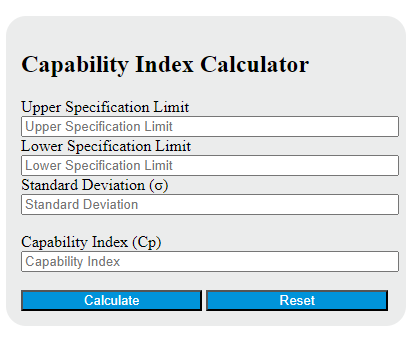

Enter the Upper Specification Limit, Lower Specification Limit, and the standard deviation of the process into the calculator to determine the Capability Index.

Capability Index Formula

The following formula is used to calculate the Capability Index.

Cp = (USL - LSL) / (6 * σ)

Variables:

- Cp is the Capability Index

- USL is the Upper Specification Limit

- LSL is the Lower Specification Limit

- σ is the standard deviation of the process

To calculate the Capability Index, subtract the Lower Specification Limit from the Upper Specification Limit. Then, multiply the standard deviation of the process by 6. Divide the first result by the second result to get the Capability Index.

What is a Capability Index?

A Capability Index is a statistical measure used in process management to assess the ability of a given process to meet specified requirements or specifications. It quantifies the alignment of the process output with the target, and the variability of the output. Common capability indices include Cp, Cpk, Pp, and Ppk, each providing different insights into process performance. A higher capability index indicates a more capable process, with less variability and fewer defects.

How to Calculate Capability Index?

The following steps outline how to calculate the Capability Index (Cp).

- First, determine the Upper Specification Limit (USL).

- Next, determine the Lower Specification Limit (LSL).

- Next, determine the standard deviation of the process (σ).

- Next, gather the formula from above = Cp = (USL – LSL) / (6 * σ).

- Finally, calculate the Capability Index (Cp).

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem:

Use the following variables as an example problem to test your knowledge.

Upper Specification Limit (USL) = 10

Lower Specification Limit (LSL) = 2

Standard Deviation (σ) = 1.5