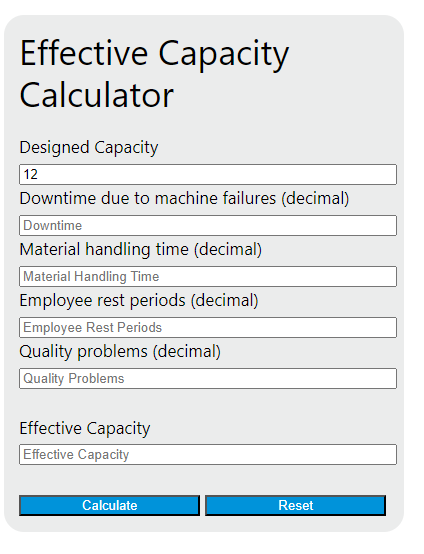

Enter the designed capacity, downtime due to machine failures, material handling time, employee rest periods, and quality problems into the calculator to determine the effective capacity.

Effective Capacity Formula

The following formula is used to calculate the effective capacity.

EC = DC * (1 - D) * (1 - M) * (1 - E) * (1 - Q)

Variables:

- EC is the effective capacity

- DC is the designed capacity

- D is the downtime due to machine failures (decimal)

- M is the material handling time (decimal)

- E is the employee rest periods (decimal)

- Q is the quality problems (decimal)

To calculate the effective capacity, start with the designed capacity. Subtract the downtime due to machine failures, material handling time, employee rest periods, and quality problems from 1 separately. Multiply these results together and then multiply the final result with the designed capacity. This will give you the effective capacity, which takes into account the realities of varying demand, machine downtime, employee rest periods, and other factors that may decrease actual output.

What is an Effective Capacity?

Effective capacity refers to the maximum amount of work that an organization is capable of completing in a given period due to constraints such as quality problems, delays, material handling, etc. It takes into account the realities of varying demand, machine downtime, employee rest periods, and other factors that may decrease actual output. It is often less than the designed capacity, which is the maximum output that can theoretically be achieved.

How to Calculate Effective Capacity?

The following steps outline how to calculate the Effective Capacity.

- First, determine the designed capacity (DC).

- Next, determine the downtime due to machine failures (D) as a decimal.

- Next, determine the material handling time (M) as a decimal.

- Next, determine the employee rest periods (E) as a decimal.

- Next, determine the quality problems (Q) as a decimal.

- Finally, calculate the Effective Capacity using the formula: EC = DC * (1 - D) * (1 - M) * (1 - E) * (1 - Q).

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

designed capacity (DC) = 100

downtime due to machine failures (D) = 0.2

material handling time (M) = 0.1

employee rest periods (E) = 0.05

quality problems (Q) = 0.15