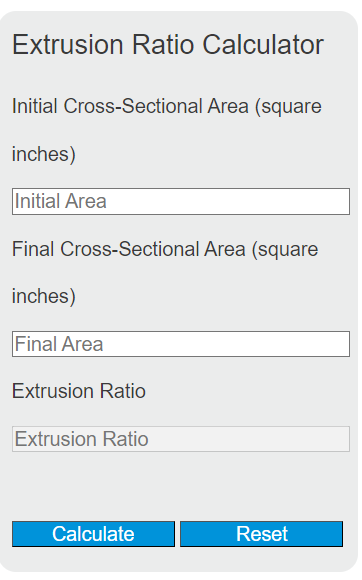

Enter the initial and final cross-sectional areas into the calculator to determine the extrusion ratio. This ratio is a measure of the degree of deformation in the extrusion process.

Extrusion Ratio Formula

The following formula is used to calculate the extrusion ratio:

ER = A₀ / A₁

Variables:

- ER is the extrusion ratio

- A₀ is the initial cross-sectional area (square inches)

- A₁ is the final cross-sectional area (square inches)

To calculate the extrusion ratio, divide the initial cross-sectional area by the final cross-sectional area.

What is an Extrusion Ratio?

The extrusion ratio is a dimensionless number that represents the amount of deformation a material undergoes during the extrusion process. It is calculated by dividing the initial cross-sectional area of the billet by the final cross-sectional area after extrusion. A higher extrusion ratio indicates a greater degree of deformation and can affect the mechanical properties of the extruded product.

How to Calculate Extrusion Ratio?

The following steps outline how to calculate the Extrusion Ratio.

- First, determine the initial cross-sectional area (A₀) in square inches.

- Next, determine the final cross-sectional area (A₁) in square inches.

- Use the formula ER = A₀ / A₁ to calculate the Extrusion Ratio (ER).

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem:

Use the following variables as an example problem to test your knowledge.

Initial cross-sectional area (A₀) = 4 square inches

Final cross-sectional area (A₁) = 1 square inch