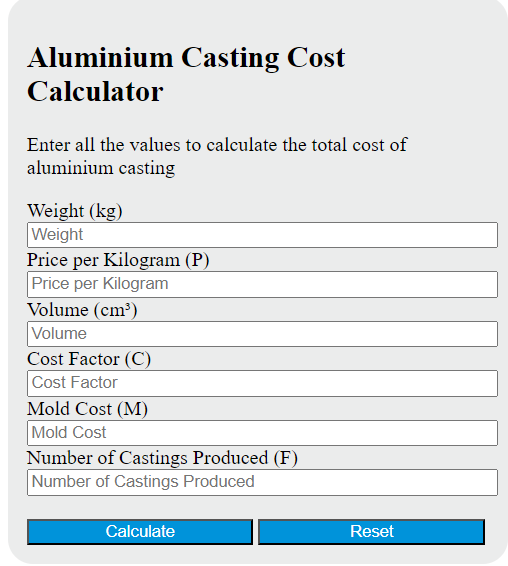

Enter all but one of the weight, price per kilogram of aluminium, volume, cost factor, mold cost, and number of castings produced from the mold into the calculator to determine the cost of aluminium casting; this calculator can also evaluate any of the variables given the others are known.

Aluminium Casting Cost Formula

The following formula is used to calculate the cost of aluminium casting:

Cost = (W * P * V * C) / (M * F)

Variables:

- Cost is the total cost of aluminium casting

- W is the weight of the casting in kilograms

- P is the price per kilogram of aluminium

- V is the volume of the casting in cubic centimeters

- C is the cost factor (e.g., overhead, labor, etc.)

- M is the mold cost

- F is the number of castings produced from the mold

To calculate the cost of aluminium casting, multiply the weight of the casting by the price per kilogram of aluminium. Multiply the result by the volume of the casting and the cost factor. Divide the product by the mold cost multiplied by the number of castings produced from the mold.

What is a Aluminium Casting Cost?

Aluminium casting cost refers to the total amount of money spent on the process of shaping aluminium into specific shapes and sizes by pouring molten aluminium into a mold and allowing it to cool and solidify. This cost includes several factors such as the cost of raw aluminium, the cost of energy used in melting and casting the aluminium, the cost of labor involved in the process, the cost of maintaining or replacing casting equipment, and the cost of quality control measures to ensure the finished product meets the required standards. Additionally, the complexity of the design, the size and weight of the cast, and the quantity of casts required can also significantly impact the overall cost. Therefore, aluminium casting cost is a comprehensive term that encompasses all the expenses associated with the aluminium casting process.