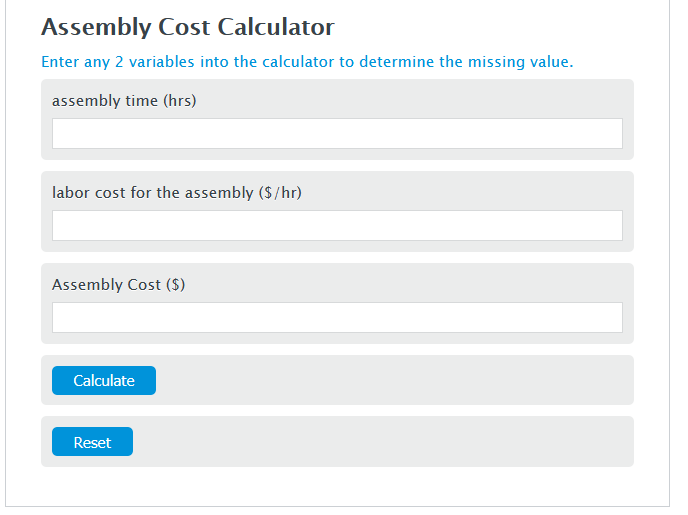

Enter the assembly time (hrs) and the labor cost for the assembly ($/hr) into the Calculator. The calculator will evaluate the Assembly Cost.

Assembly Cost Formula

AC = AT * LC

Variables:

- AC is the Assembly Cost ($)

- AT is the assembly time (hrs)

- LC is the labor cost for the assembly ($/hr)

To calculate the Assembly Cost, multiply the assembly time by the labor rate for assembly.

How to Calculate Assembly Cost?

The following steps outline how to calculate the Assembly Cost.

- First, determine the assembly time (hrs).

- Next, determine the labor cost for the assembly ($/hr).

- Next, gather the formula from above = AC = AT * LC.

- Finally, calculate the Assembly Cost.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

assembly time (hrs) = 30

labor cost for the assembly ($/hr) = 50

FAQs

What factors can affect the assembly time of a product?

Several factors can affect the assembly time, including the complexity of the product, the skill level of the workforce, the efficiency of the assembly process, and the quality of the components being assembled.

How can a company reduce its assembly costs?

Companies can reduce assembly costs by optimizing the assembly process for efficiency, training workers to improve their skills, investing in automation where feasible, and negotiating better rates for labor and materials.

Are there any software tools that can help calculate assembly costs more efficiently?

Yes, there are several software tools and platforms that offer advanced features for calculating assembly costs, including process simulation, cost estimation, and project management tools, which can help in more accurately forecasting and reducing assembly costs.

Can the assembly cost formula be applied to any type of product assembly?

The basic assembly cost formula (AC = AT * LC) is versatile and can be applied to a wide range of product assemblies. However, for more complex assemblies involving multiple stages or different types of labor, a more detailed cost analysis may be necessary.