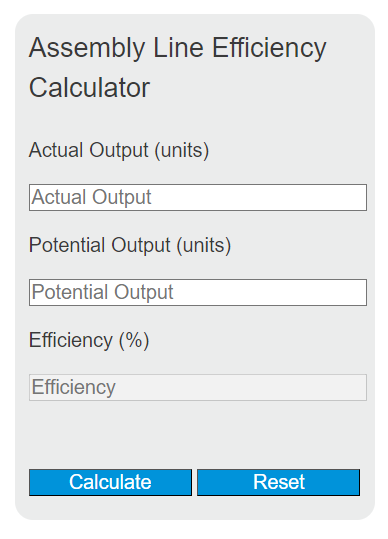

Enter the actual and potential output of an assembly line into the calculator to determine its efficiency as a percentage.

Assembly Line Efficiency Formula

The following formula is used to calculate the efficiency of an assembly line.

E = (AO / PO) * 100

Variables:

- E is the efficiency of the assembly line (%)

- AO is the actual output of the assembly line (units)

- PO is the potential output of the assembly line (units)

To calculate the efficiency of an assembly line, divide the actual output by the potential output and then multiply by 100 to get the percentage.

What is Assembly Line Efficiency?

Assembly line efficiency is a measure of how well an assembly line is performing compared to its potential output. It is a key performance indicator in manufacturing and production environments, reflecting the percentage of the potential output that is actually being achieved. High efficiency indicates that the assembly line is operating close to its maximum capacity, while low efficiency suggests there may be issues that need to be addressed to improve performance.

How to Calculate Assembly Line Efficiency?

The following steps outline how to calculate the Assembly Line Efficiency.

- First, determine the actual output of the assembly line (AO) in units.

- Next, determine the potential output of the assembly line (PO) in units.

- Next, gather the formula from above = E = (AO / PO) * 100.

- Finally, calculate the Assembly Line Efficiency (E) in percentage.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

actual output of the assembly line (AO) = 450 units

potential output of the assembly line (PO) = 500 units