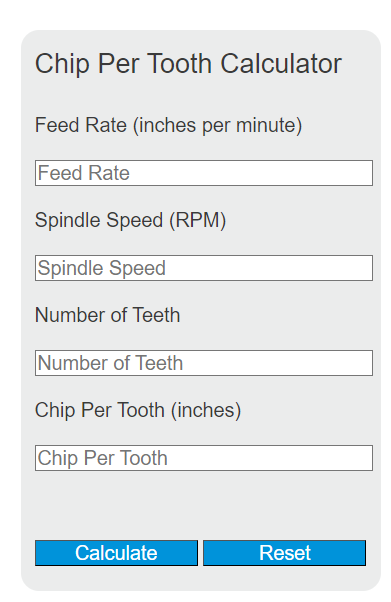

Enter the feed rate, spindle speed, and number of teeth into the calculator to determine the chip per tooth. This calculator helps in optimizing the milling process by calculating the thickness of the chip that each tooth on a milling cutter will produce.

Chip Per Tooth Formula

The following formula is used to calculate the chip per tooth.

CPT = {FR}/({SS *NT})Variables:

- CPT is the chip per tooth (inches)

- FR is the feed rate (inches per minute)

- SS is the spindle speed (revolutions per minute)

- NT is the number of teeth on the cutter

To calculate the chip per tooth, divide the feed rate by the product of the spindle speed and the number of teeth on the cutter.

What is Chip Per Tooth?

Chip per tooth is a measure of the thickness of the material removed by each tooth of a cutting tool, such as a milling cutter, during one revolution. It is a critical parameter in machining that affects the surface finish, cutting forces, tool life, and the overall efficiency of the machining process. Proper selection of chip per tooth values can lead to improved productivity and better quality of the machined parts.

How to Calculate Chip Per Tooth?

The following steps outline how to calculate the Chip Per Tooth.

- First, determine the feed rate (FR) in inches per minute.

- Next, determine the spindle speed (SS) in revolutions per minute.

- Next, determine the number of teeth (NT) on the cutter.

- Next, gather the formula from above = CPT = FR / (SS * NT).

- Finally, calculate the Chip Per Tooth (CPT) in inches.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

Feed Rate (FR) = 100 inches per minute

Spindle Speed (SS) = 2000 RPM

Number of Teeth (NT) = 4