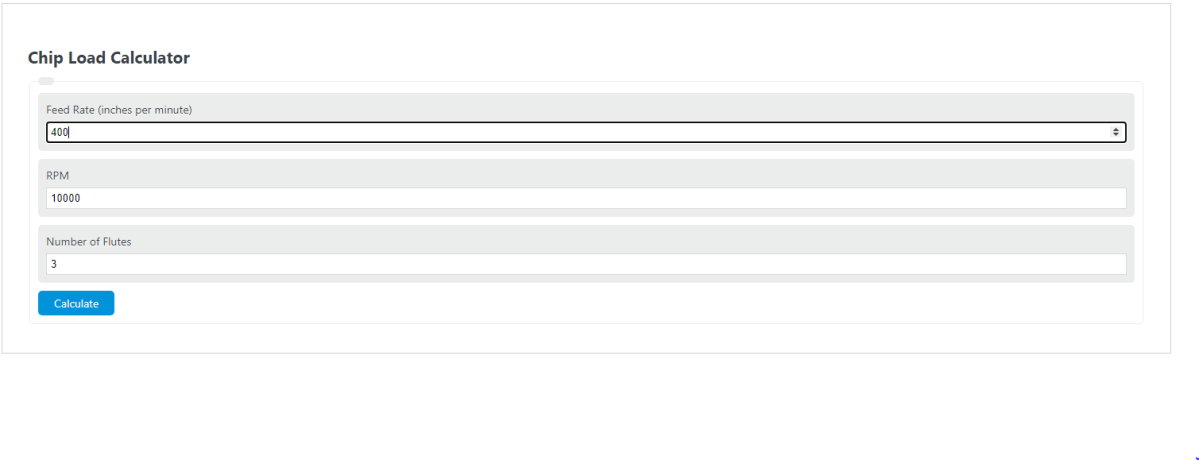

Enter the feed rate, RPM, and the number of flutes into the calculator to determine the chip load.

- Material Removal Rate Calculator

- Drill SFM Calculator

- Surface Speed (SFM) Calculator

- Spindle Speed Calculator

- Cycle Time Calculator

- Countersink Depth Calculator

- Wood Lathe Speed Calculator

- Cutting Force Calculator

- Chip Thinning Factor Calculator

Chip Load Formula

The following formula is used to calculate the chip load of a machining process.

CL = FR / (RPM * F)

- Where CL is the chip load (inches)

- FR is the feed rate (inches per minute)

- RPM is the rotation of the spindle (rotations per minute)

- F is the number of flutes on the tool

To calculate a chip load, divide the feed rate by the product of the RPM and the number of flutes on the tool.

What is a chip load?

Definition:

A chip load is a measure of the thickness of material that is moved by each cutting edge during a cut.

So, the greater the number of flutes, the smaller the chip load and vise versa.

How to calculate a chip load?

Example:

The following example problem outlines the information and steps needed to calculate a chip load.

First, determine the feed rate. For this example, the feed rate is measured to be 400 inches per minute.

Next, determine the RPM of the spindle. In this case, the RPM is measured to be 10,000.

Next, determine the number of flutes on the tool. The tool being used for this cutting procedure has 3 flutes.

Finally, calculate the chip load using the formula above:

CL = FR / (RPM * F)

CL = 400 / (10,000 *3)

CL = .0133 inches