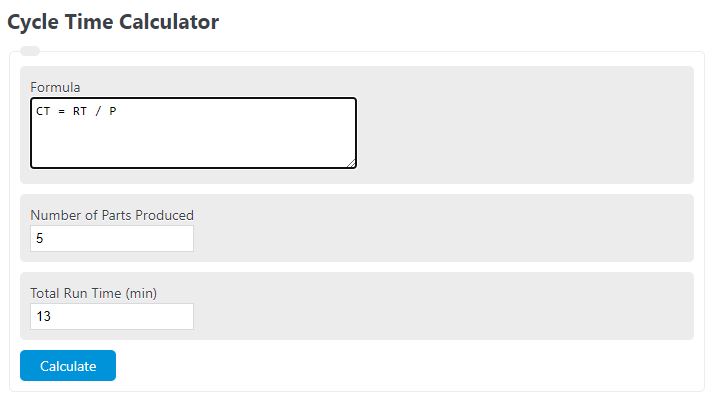

Enter the total number of parts produced and the total production time into the calculator to determine the cycle time. This calculator can also evaluate the units produced or total time given the other variables.

- Takt Time Calculator

- Labor Productivity Calculator

- Units of Production Depreciation Calculator

- Throughput Time Calculator

- Rotary Airlock Valve Capacity Calculator

- Process Cycle Time Reduction Calculator

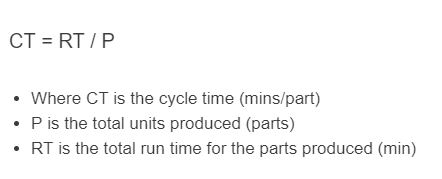

Cycle Time Formula

The following formula is used to calculate the cycle time of a produced product.

CT = RT / P

- Where CT is the cycle time (mins/part)

- P is the total units produced (parts)

- RT is the total run time for the parts produced (min)

To calculate cycle time, divide the total run time by the total number of units produced.

Cycle Time Definition

A cycle time is defined as the total time it takes to produce one unit of a product or manufactured good.

Cycle Time Example

How to calculate cycle time?

- First, determine the number of parts produced in a shift.

For this example, we will say that 1000 parts were made.

- Next, determine the length of the shift.

For this example, we will assume a standard shift of 8 hours = 480 min.

- Finally, calculate the cycle time.

Using the formula we find the cycle time to be 1000/480 = 2.083 min/part.

FAQ

A cycle time is a measure of how long it takes to produce a given part. For example, a part may take 20min to run 10 parts. The cycle time is then described as 2 min per part.