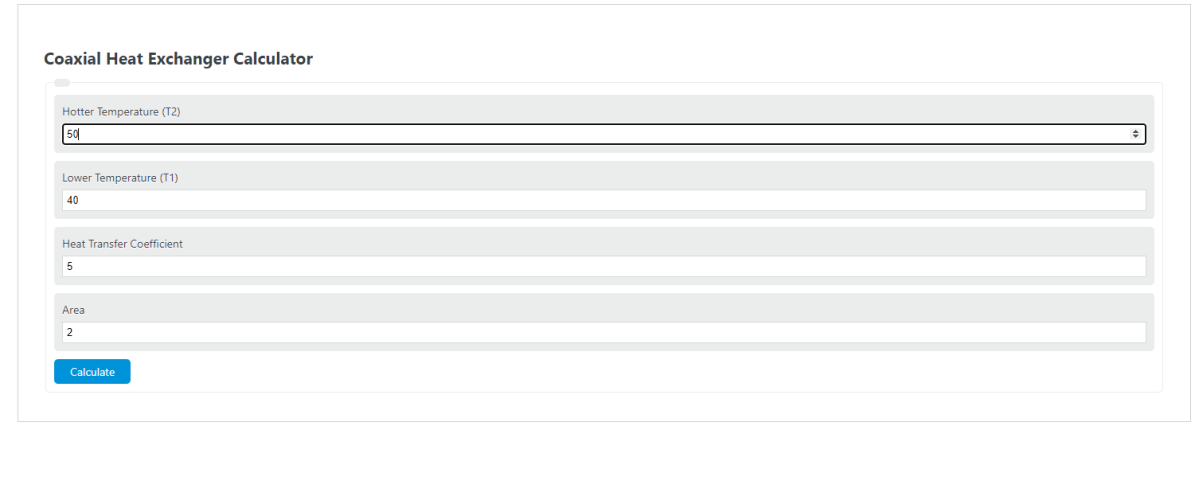

Enter the heat transfer coefficient, heat transfer area, inlet temperature, and outlet temperature into the calculator to determine the coaxial heat exchange.

- Heat Exchanger Effectiveness Calculator

- LMTD (Logarithmic Mean Temperature Difference) Calculator

- Thermal Efficiency Calculator

- Plate Heat Exchanger Capacity Calculator

Coaxial Heat Exchanger Formula

The following formula is used to calculate the total heat exchange of a coaxial heat exchanger.

Q = U * A * LMTD

- Where Q is the heat exchange rate (kJ/hr)

- A is the total heat transfer area (m^2)

- U is the overall heat transfer coefficient (kJ/(hr*m^2*C))

- LMTD is the log mean temperature difference

To calculate the heat exchange rate of a coaxial heat exchanger, multiply the heat transfer coefficient by the area, then multiply by the log mean temperature difference.

What is a coaxial heat exchanger?

A coaxial heat exchanger is a vital component used in various industries to transfer heat between two fluids efficiently. It consists of two concentric tubes, one placed inside the other, with the fluids flowing in opposite directions. The inner tube carries one fluid while the outer tube carries the other fluid. The separation between the tubes allows for the exchange of thermal energy without directly mixing the fluids.

How to calculate coaxial heat exchange?

Example Problem:

The following example outlines how to calculate the heat exchange rate of a coaxial heat exchanger.

First, determine the area of heat transfer. In this example, the area is 2 m^2.

Next, determine the inlet and outlet temperatures. For this example, these are 50C and 40C respectively.

Next, using the inlet and outlet temperatures, calculate the log mean temperature difference. Using the calculated linked above, this is found to be: 44.81

Next, determine the overall heat transfer coefficient. This is determined to be 5 kJ/(h*m^2*c).

Finally, calculate the heat exchange rate using the formula above:

Q = U * A * LMTD

Q = 5 * 2 * 44.81

Q = 448.1 kJ/hr

FAQ

What factors can affect the overall heat transfer coefficient in a coaxial heat exchanger?

The overall heat transfer coefficient in a coaxial heat exchanger can be influenced by several factors, including the types of fluids involved, their flow rates, the materials of the tubes, and the presence of any fouling on the tube surfaces. The fluid’s viscosity, temperature, and thermal conductivity also play significant roles in determining the heat transfer efficiency.

How does the flow arrangement (counterflow, parallel flow) affect the performance of a coaxial heat exchanger?

In a coaxial heat exchanger, the counterflow arrangement, where the fluids flow in opposite directions, typically offers higher thermal efficiency than the parallel flow arrangement, where fluids flow in the same direction. This is because the counterflow arrangement maintains a higher temperature gradient along the length of the exchanger, enhancing the heat transfer rate.

Can the log mean temperature difference (LMTD) method be used for all types of heat exchangers?

The log mean temperature difference (LMTD) method is a widely used approach for calculating the heat transfer rate in heat exchangers, including coaxial types. However, its applicability depends on the exchanger operating under steady-state conditions and with a constant flow arrangement. For varying conditions, other methods like the effectiveness-NTU method might be more appropriate.