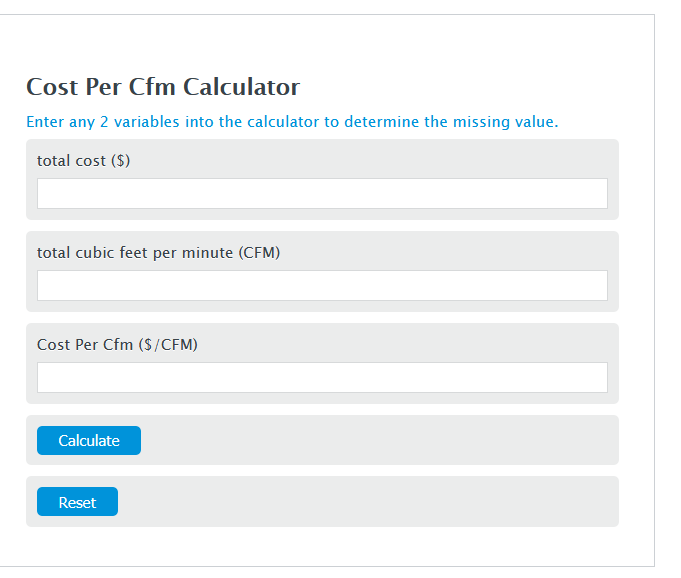

Enter the total cost ($) and the total cubic feet per minute (CFM) into the Calculator. The calculator will evaluate the Cost Per Cfm.

Cost Per Cfm Formula

CCFM = TC / TCFM

Variables:

- CCFM is the Cost Per Cfm ($/CFM)

- TC is the total cost ($)

- TCFM is the total cubic feet per minute (CFM)

To calculate Cost Per Cfm, divide the total cost by the cubic feet per minute of flow.

How to Calculate Cost Per Cfm?

The following steps outline how to calculate the Cost Per Cfm.

- First, determine the total cost ($).

- Next, determine the total cubic feet per minute (CFM).

- Next, gather the formula from above = CCFM = TC / TCFM.

- Finally, calculate the Cost Per Cfm.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

total cost ($) = 838821

total cubic feet per minute (CFM) = 191

FAQs

What is CFM and why is it important?

CFM stands for Cubic Feet per Minute. It is a measure of airflow volume and is important for determining the efficiency of HVAC systems, fans, and other air flow-related processes. Understanding CFM is crucial for ensuring adequate ventilation and air quality in a space.

How can calculating Cost Per CFM help in managing expenses?

Calculating Cost Per CFM helps in understanding the cost-effectiveness of air flow systems. By knowing how much it costs to move a cubic foot of air per minute, businesses and individuals can make informed decisions about their HVAC systems, potentially leading to cost savings and more efficient energy use.

Are there any other calculators related to CFM that I might find useful?

Yes, there are several related calculators that can be useful depending on your needs. For example, the CCF to Therms Calculator for energy conversions, the CFM to FPS (Feet per Second) Calculator for speed conversions, and the Evaporative Cooler CFM Calculator for determining the appropriate size of an evaporative cooler based on CFM requirements.

What factors can affect the CFM in a system?

Several factors can affect the CFM in a system, including the size and design of the ductwork, the power and efficiency of fans and blowers, the level of obstruction in the air path, and the overall design of the HVAC system. Regular maintenance and proper design considerations can help optimize CFM and improve system efficiency.