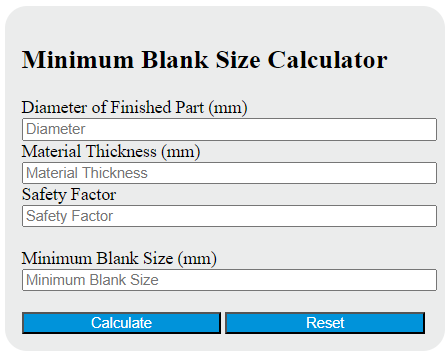

Enter the diameter of the finished part, material thickness, and safety factor into the calculator to determine the minimum blank size. This calculator can also evaluate any of the variables given the others are known.

Minimum Blank Size Formula

The following formula is used to calculate the minimum blank size.

MBS = (D + 2 * M) * S

Variables:

- MBS is the minimum blank size (mm)

- D is the diameter of the finished part (mm)

- M is the material thickness (mm)

- S is the safety factor (unitless)

To calculate the minimum blank size, add twice the material thickness to the diameter of the finished part. Multiply the result by the safety factor.

What is a Minimum Blank Size?

A Minimum Blank Size refers to the smallest size of a sheet or piece of material that can be used in a manufacturing process, such as stamping or cutting, to create a specific part or product. This size is determined by the dimensions of the final product, the type of material being used, and the specific manufacturing process. It is important to calculate the minimum blank size accurately to minimize waste and reduce production costs.

How to Calculate Minimum Blank Size?

The following steps outline how to calculate the Minimum Blank Size.

- First, determine the diameter of the finished part (D) in millimeters.

- Next, determine the material thickness (M) in millimeters.

- Next, determine the safety factor (S) which is a unitless value.

- Next, use the formula MBS = (D + 2 * M) * S to calculate the Minimum Blank Size (MBS) in millimeters.

- Finally, calculate the Minimum Blank Size using the values of D, M, and S.

Example Problem :

Use the following variables as an example problem to test your knowledge.

Diameter of the finished part (D) = 50 mm

Material thickness (M) = 5 mm

Safety factor (S) = 1.5