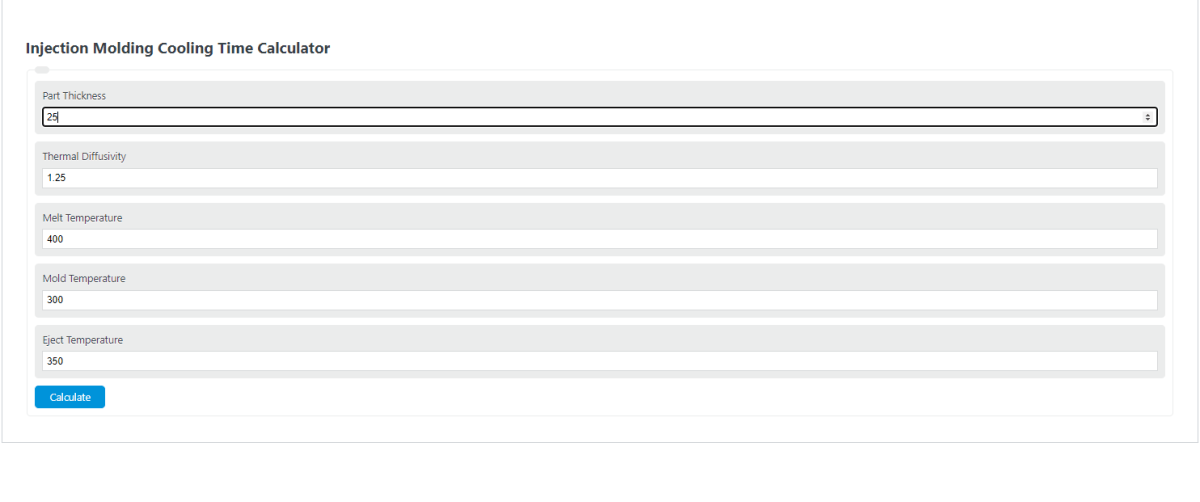

Enter the melt temperature, mold temperature, ejection temperature, part thickness, and thermal diffusivity into the calculator to determine the injection molding cooling time.

- Evaporative Cooling Calculator

- Cooling Capacity Calculator

- Subcooling Calculator

- Newton’s Law of Cooling Calculator

- Extruder Power Calculator

- Cooling Tower Capacity Calculator

- Cooling Tower Performance Calculator

- Extrusion Force Calculator

Injection Molding Cooling Time Formula

The following formula is used to calculate the Injection Molding Cooling Time.

t = (h^2/(2*pi*a)) * ln [ 4/pi * (Tm – Tmo) / (Teject – Tmo) ]

- Where t is the cooling time

- h is the part thickness

- a is the thermal diffusivity

- Tm is the melt temperature

- Tmo is the mold temperature

- Teject is the ejection temperature

What is an injection molding cooling time?

Definition:

An injection molding cooling time is the total amount of time it takes a material in an injection molder to cool to a point where it can be removed from the molder without distortion.

Typically, 80% of the time of an injection molder is spent cooling the product.

How to calculate injection molding cooling time?

Example Problem:

The following example outlines how to calculate an injection molding cooling time.

First, determine the part thickness. In this example, the part thickness is 25 mm.

Next, determine the thermal diffusivity. This is calculated to be 1.25.

Next, determine the melt temperature of the material. This material has a melt temperature of 400 F.

Next, determine the mold temperature. This is measured to be 300F.

Next, determine the eject temperature. This is calculated to be 350F.

Finally, calculate the cooling time using the formula above:

t = (h^2/(2*pi*a)) * ln [ 4/pi * (Tm – Tmo) / (Teject – Tmo) ]

t = (25^2/(2*3.14159*1.25)) * ln [ 4/3.14159 * (400- 300) / (350 – 300) ]

t = 74.38 s

FAQ

What factors can affect the accuracy of the injection molding cooling time calculation?

The accuracy of the injection molding cooling time calculation can be affected by several factors, including the precision of the input values (part thickness, thermal diffusivity, melt temperature, mold temperature, and ejection temperature), the consistency of the material properties, and variations in the manufacturing environment such as ambient temperature and humidity.

How can optimizing the injection molding cooling time benefit the manufacturing process?

Optimizing the injection molding cooling time can significantly benefit the manufacturing process by reducing cycle times, improving product quality, minimizing warping or distortion of parts, and increasing overall production efficiency. It can also lead to energy savings and reduced operational costs.

Are there any software tools available that can help with the calculation of injection molding cooling time?

Yes, there are several software tools and simulation programs available that can assist with the calculation of injection molding cooling time. These tools often provide more comprehensive analysis by considering complex geometries, varying material properties, and other process parameters. They can help predict cooling time more accurately and suggest optimizations for the injection molding process.