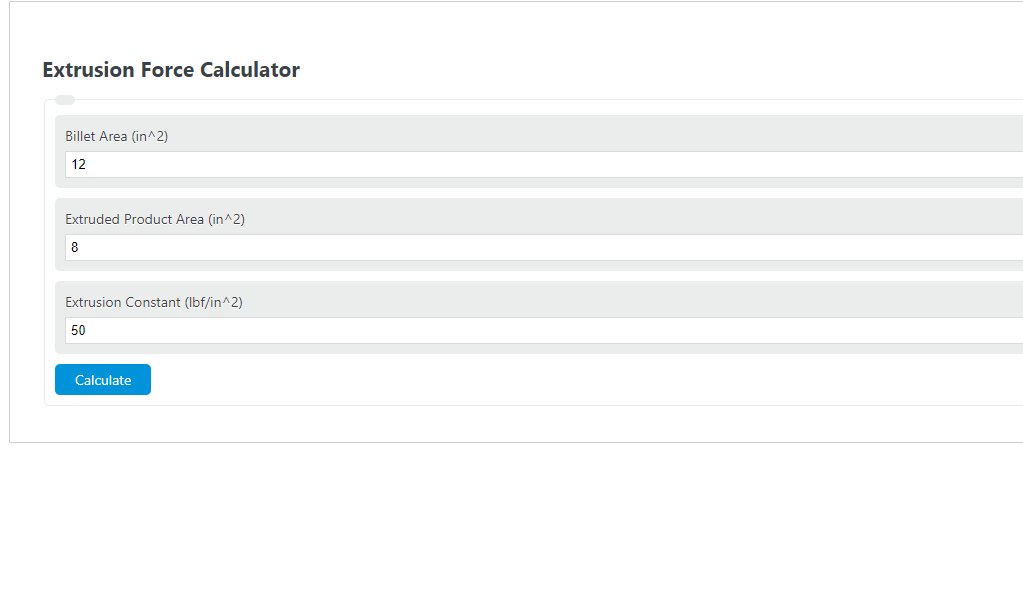

Enter the billet area, extruded product area, and the extrusion constant into the calculator to determine the extrusion force.

- All Force Calculators

- Extruder Power Calculator

- Injection Molding Cooling Time Calculator

- Injector Duty Cycle Calculator

Extrusion Force Formula

The following equation is used to calculate the Extrusion Force.

EF = A0 * k * ln ( A0/Af)

- Where EF is the extrusion force (lbf)

- A0 is the billet area (in^2)

- Af is the extruded product area (in^2)

- k is the extrusion constant (lbf/in^2)

To calculate the extrusion force, multiply the billet area by the extrusion constant, then multiply by the natural log of the ratio of the billet area to the extruded product area.

What is an Extrusion Force?

Definition:

An Extrusion Force measures the amount of force it takes to extrude (or push) plastic into a die. The force is measured in pounds or Newtons. The higher the force, the more difficult it is to extrude a part.

How to Calculate Extrusion Force?

Example Problem:

The following example outlines the steps and information needed to calculate the Extrusion Force.

First, determine the billet area. In this example, the billet area is measured to be 12 in^2.

Next, determine the extruded product area. The extruded product area in this problem is 8 in^2.

Next, determine the extrusion constant. This is calculated to be 50 lbf/in^2.

Finally, calculate the extrusion force using the formula above;

EF = A0 * k * ln ( A0/Af)

EF = 12 * 50 * ln ( 12/8)

EF = 243.27 lbf

FAQ

What factors can affect the extrusion force required during the extrusion process?

The extrusion force can be affected by several factors including the material being extruded, the temperature at which extrusion is performed, the speed of extrusion, the design of the die, and the lubrication used during the process. Materials with higher viscosity or those that are more resistant to flow require higher extrusion forces. Similarly, lower temperatures can increase the force required due to the reduced material flowability.

How does the extrusion constant (k) vary between different materials?

The extrusion constant (k) is a material-specific parameter that quantifies the resistance of the material to being extruded. It varies significantly between different materials, depending on their mechanical properties and behavior under stress. For example, metals typically have higher extrusion constants than plastics due to their higher density and strength. The exact value for a specific material can be determined through empirical testing or sourced from material property databases.

Can the extrusion force formula be used for materials other than plastics, such as metals?

Yes, the extrusion force formula provided can be applied to a wide range of materials, including metals and polymers. The key is to correctly determine the extrusion constant (k) for the material in question, as this value encapsulates the material’s resistance to deformation under the extrusion process. However, it’s important to note that for very ductile metals or materials with complex behavior under pressure, additional factors might need to be considered for accurate force prediction.