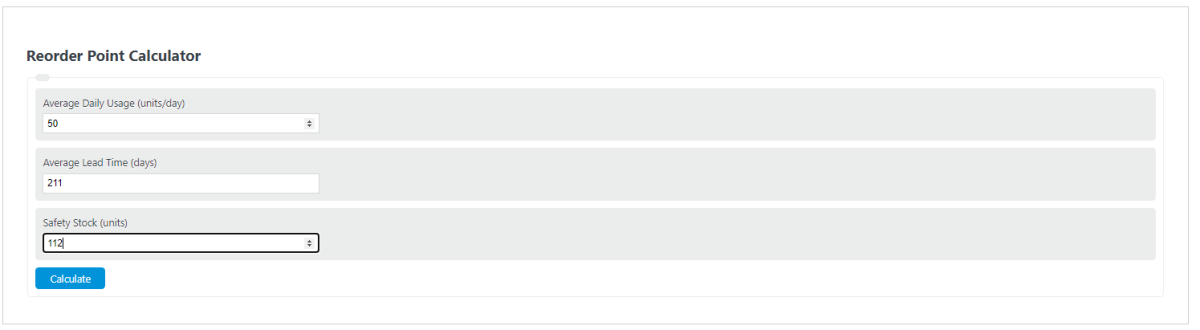

Enter the average daily usage, lead time, and safety stock into the calculator to determine the reorder point and lead time demand.

- Safety Stock Calculator

- Stocking Rate Calculator

- Inventory Turnover Ratio Calculator

- Days In Inventory Calculator

- LIFO (Last-In, First-Out) Calculator

- Optimal Stock Level Calculator

- Stock Out Probability Calculator

- Inventory To Sales Ratio Calculator

Reorder Point Formula

The following formula is used to calculate a reorder point.

RP = LT * ADU + SS

- Where RP is the reorder point

- LT is the lead time (days)

- ADU is the average daily usage

- SS is the safety stock

To calculate the reorder point, multiply the lead time by the average daily usage, then add in the safety stock

The product of the lead time and average daily usage is also known as the lead time demand.

Reorder Point Definition

A reorder point is defined as the point or quantity of goods at which a company should reorder more products from their supplier or suppliers.

The reorder point is based on the usage, lead time, and safety stock the business once to hold. Safety stock is a measure of the number of units a company holds on hand above their required usage for cases of emergency.

Example Problem

How to calculate a reorder point?

First, determine the lead time of the product. For this example, we are looking at a candy store that is replenishing their favorite selling candy bar. The lead time for that bar is 10 days.

Next, determine the average daily number of units sold. This candy bar sells a modest 40 units per day.

Next, multiply the lead time by the number of units sold. This result will be your “lead time demand”. So, 40*10=400.

Next, determine the safety stock the company wishes to have on hand. In cases of emergency, this store would like 200 candy bars in safety stock.

Finally, add the lead time demand to the safety stock to get the reorder point.

400 + 200 = 600.

This store should order new candy bars any time their stock levels reach 600 units.