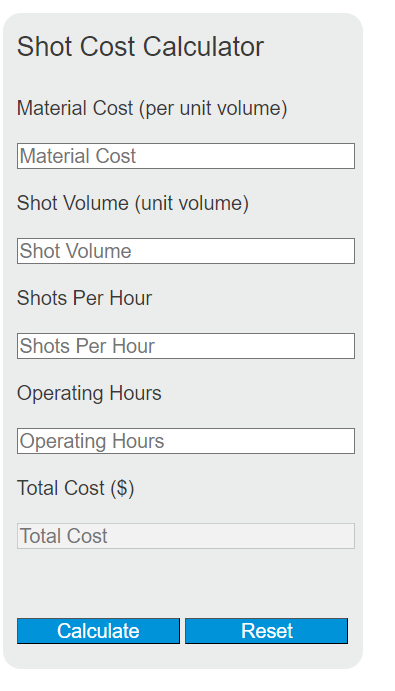

Enter the material cost per unit volume, shot volume, shots per hour, and operating hours into the calculator to determine the total cost of production shots.

Shot Cost Formula

The following formula is used to calculate the total cost of production shots.

TC = MC * SV * SPH * OH

Variables:

- TC is the total cost ($)

- MC is the material cost per unit volume ($/unit volume)

- SV is the shot volume (unit volume)

- SPH is the number of shots per hour

- OH is the operating hours

To calculate the total cost, multiply the material cost per unit volume by the shot volume, the number of shots per hour, and the operating hours.

What is Shot Cost?

Shot cost is the total expense incurred for producing a certain number of shots in manufacturing processes such as injection molding. It includes the cost of the raw material used per shot, the number of shots produced per hour, and the total operating hours. This cost is crucial for determining the efficiency and profitability of the production process.

How to Calculate Shot Cost?

The following steps outline how to calculate the Shot Cost.

- First, determine the material cost per unit volume (MC).

- Next, determine the shot volume (SV).

- Next, determine the number of shots per hour (SPH).

- Next, determine the operating hours (OH).

- Next, gather the formula from above = TC = MC * SV * SPH * OH.

- Finally, calculate the total cost (TC).

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

material cost per unit volume (MC) = $0.05 per cubic inch

shot volume (SV) = 10 cubic inches

shots per hour (SPH) = 100

operating hours (OH) = 8