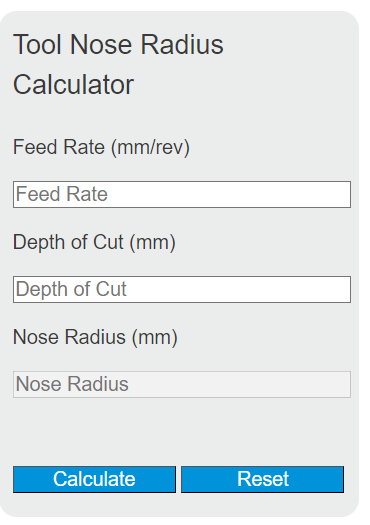

Enter the feed rate and the depth of cut into the calculator to determine the tool nose radius. This calculator helps in selecting the appropriate tool for turning operations based on the desired surface finish and cutting conditions.

Tool Nose Radius Formula

The following formula is used to calculate the tool nose radius.

NR = √(FR * DOC)

Variables:

- NR is the tool nose radius (mm)

- FR is the feed rate (mm per revolution)

- DOC is the depth of cut (mm)

To calculate the tool nose radius, take the square root of the product of the feed rate and the depth of cut.

What is a Tool Nose Radius?

The tool nose radius is the radius of the rounded tip of a cutting tool used in turning operations. It is an important parameter that affects the surface finish of the machined part, the cutting forces, and the tool life. A larger nose radius can improve the surface finish and distribute the cutting forces over a larger area, reducing wear on the tool. However, it may also require more cutting power and could lead to chatter or poor surface finish if not matched with the appropriate feed rate and depth of cut.

How to Calculate Tool Nose Radius?

The following steps outline how to calculate the Tool Nose Radius.

- First, determine the feed rate (FR) in mm per revolution.

- Next, determine the depth of cut (DOC) in mm.

- Next, gather the formula from above = NR = √(FR * DOC).

- Finally, calculate the Tool Nose Radius (NR) in mm.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

Feed rate (FR) = 0.2 mm/rev

Depth of cut (DOC) = 2 mm