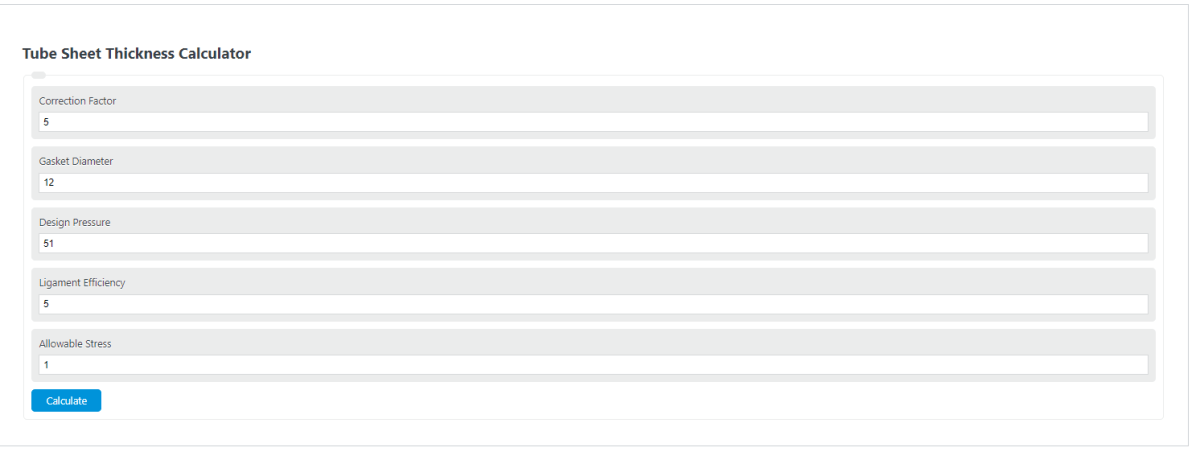

Enter the allowable stress, design pressure, ligament efficiency, gasket effective diameter, and the correction factor into the calculator to determine the tube sheet thickness.

- Plate Thickness Calculator

- Outer Radius of a Hollow Tube Calculator

- Plate Heat Exchanger Capacity Calculator

Tube Sheet Thickness Formula

The following equation is used to calculate the Tube Sheet Thickness.

T= F*G / 3 * SQRT ( P/n*S)

- Where T is the effective tube sheet thickness

- F is the correction factor

- G is the gasket diameter

- P is the design pressure

- n is the ligament efficiency

- S is the allowable stress

What is a Tube Sheet Thickness?

Definition:

A tube sheet thickness is the most effective thickness of a tube sheet needed for bending.

How to Calculate Tube Sheet Thickness?

Example Problem:

The following example outlines the steps and information needed to calculate Tube Sheet Thickness.

First, determine the correction factor. In this example, the correction factor will be 1.

Next, determine the gasket diameter. The gasket diameter in this case is measured to be 4.

Next, determine the design pressure. This is given as 5.

Next, determine the ligament efficiency. This is calculated as .75.

Next, determine the allowable stress. The allowable stress for this problem is 500.

Finally, calculate the tube sheet thickness using the formula above:

T= F*G / 3 * SQRT ( P/n*S)

T= 1*4 / 3 * SQRT ( 5/.75*500)

T= 76.98