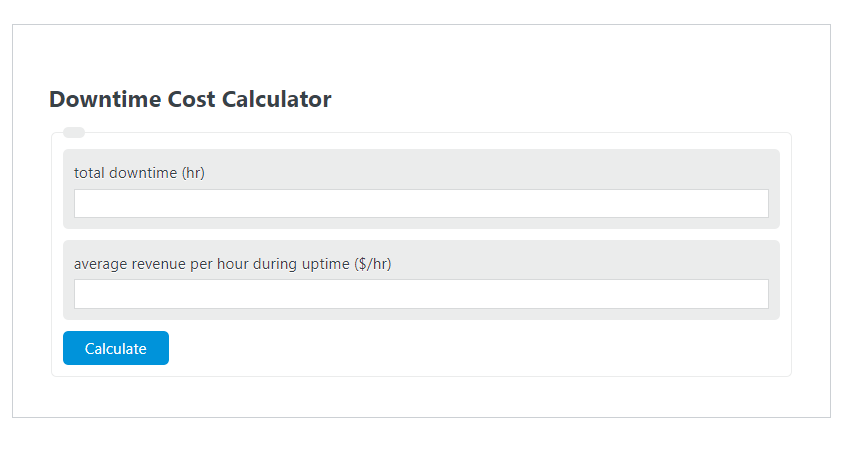

Enter the total downtime (hr) and the average revenue per hour during uptime ($/hr) into the Downtime Cost Calculator Calculator. The calculator will evaluate and display the Downtime Cost.

- All Cost Calculators

- MTR (Mean-Time-To-Repair) Calculator

- Capitalized Cost Calculator

- Machinery Cost Calculator

Downtime Cost Formula

The following formula is used to calculate the Downtime Cost Calculator.

DC = DT * ARU

- Where DC is the Downtime Cost ($)

- DT is the total downtime (hr)

- ARU is the average revenue per hour during uptime ($/hr)

To calculate the downtime cost, multiply the total downtime by the average revenue per hour.

How to Calculate Downtime Cost?

The following example problems outline how to calculate Downtime Cost.

Example Problem #1:

- First, determine the total downtime (hr). The total downtime (hr) is given as 5.

- Next, determine the average revenue per hour during uptime ($/hr). The average revenue per hour during uptime ($/hr) is provided as 200.

- Finally, calculate the downtime cost using the equation above:

DC = DT * ARU

The values given above are inserted into the equation below:

DC = 5 * 200 = 1,000.00 ($)

FAQ

What factors can contribute to increased downtime costs?

Several factors can contribute to increased downtime costs, including lost sales, increased labor costs for repairs, potential penalties for missed deadlines, loss of customer trust, and the opportunity cost of not being able to generate revenue during the downtime period.

How can businesses reduce downtime costs?

Businesses can reduce downtime costs by implementing preventive maintenance schedules, investing in high-quality machinery and equipment, training employees on proper operation procedures, having a contingency plan in place, and using downtime tracking and analysis tools to identify and address recurring issues.

Are there any tools or software that can help predict or manage downtime costs?

Yes, there are several tools and software solutions available that can help businesses predict or manage downtime costs. These include maintenance management software (CMMS), enterprise resource planning (ERP) systems with maintenance modules, predictive maintenance tools using IoT and AI technologies, and downtime tracking and analysis software that helps identify patterns and potential issues before they lead to significant downtime.