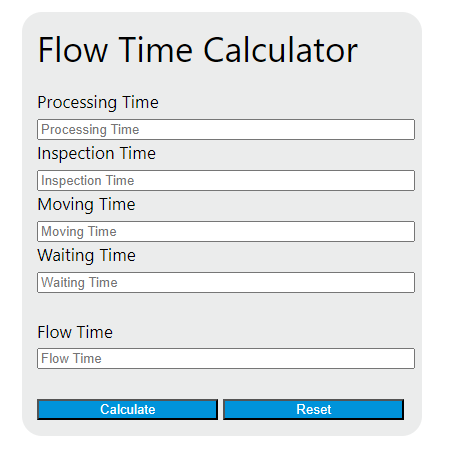

Enter the processing time, inspection time, moving time, and waiting time into the calculator to determine the flow time.

Flow Time Formula

The following formula is used to calculate the flow time.

FT = P + I + M + W

Variables:

- FT is the flow time (hours, days, etc.)

- P is the processing time (hours, days, etc.)

- I is the inspection time (hours, days, etc.)

- M is the moving time (hours, days, etc.)

- W is the waiting time (hours, days, etc.)

To calculate the flow time, add the processing time, inspection time, moving time, and waiting time together. This will give you the total time taken for a product, service, or task to move from the beginning to the end of a process. Reducing any of these times can help to increase efficiency and productivity in a process.

What is a Flow Time?

Flow time, also known as throughput time, is the total time taken for a product, service, or task to move from the beginning to the end of a process. It includes the time taken for processing, inspection, moving, and waiting. In manufacturing or production, it is the time taken from the start of production to the completion of the product. Reducing flow time can increase efficiency and productivity in a process.

How to Calculate Flow Time?

The following steps outline how to calculate the Flow Time using the given formula:

- First, determine the processing time (P) in hours, days, etc.

- Next, determine the inspection time (I) in hours, days, etc.

- Next, determine the moving time (M) in hours, days, etc.

- Finally, determine the waiting time (W) in hours, days, etc.

- After obtaining the values for P, I, M, and W, substitute them into the formula FT = P + I + M + W.

- Calculate the Flow Time using the formula.

Example Problem:

Use the following variables as an example problem to test your knowledge:

Processing time (P) = 5 hours

Inspection time (I) = 2 hours

Moving time (M) = 3 hours

Waiting time (W) = 1 hour