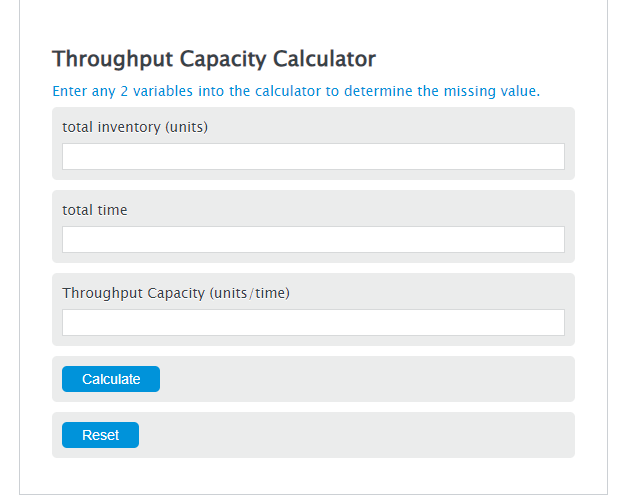

Enter the total inventory (units) and the total time into the Calculator. The calculator will evaluate the Throughput Capacity.

Throughput Capacity Formula

TC = I / T

Variables:

- TC is the Throughput Capacity (units/time)

- I is the total inventory (units)

- T is the total time

To calculate Throughput Capacity, divide the total inventory by the total time.

How to Calculate Throughput Capacity?

The following steps outline how to calculate the Throughput Capacity.

- First, determine the total inventory (units).

- Next, determine the total time.

- Next, gather the formula from above = TC = I / T.

- Finally, calculate the Throughput Capacity.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

total inventory (units) = 30

total time = 20

FAQ

What is Throughput Capacity in manufacturing?

Throughput Capacity in manufacturing refers to the maximum rate at which units can be processed within a given time period without compromising the quality of the output. It’s a critical measure for understanding operational efficiency and optimizing production processes.

How can improving Throughput Capacity benefit a business?

Improving Throughput Capacity can significantly benefit a business by increasing production output, reducing lead times, improving customer satisfaction, and potentially lowering operational costs. This, in turn, can lead to increased sales and profitability.

Are there common strategies to increase Throughput Capacity?

Yes, common strategies include streamlining production processes, reducing non-value-added activities, optimizing the workforce, implementing better maintenance schedules for machinery, and adopting technology and automation.

How does inventory level affect Throughput Capacity?

Inventory levels directly impact Throughput Capacity as excessive inventory can lead to congestion and slower production times, while too little inventory can cause delays and stoppages. Optimal inventory management is crucial for maintaining efficient throughput.