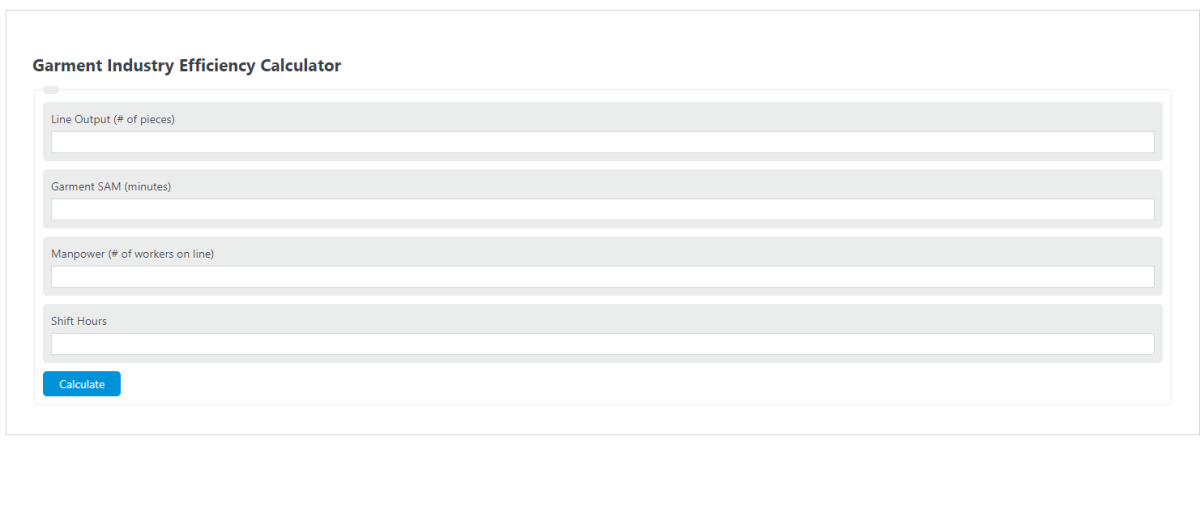

Enter the line output, Garment SAM, manpower, and shift hours into the calculator to determine the garment line efficiency.

- All Efficiency Calculators

- Condenser Efficiency Calculator

- Mean Time To Failure (MTTF) Calculator

- Yarn Production Calculator

- Fabric Weight Calculator

- Production Efficiency Calculator

- Efficiency Of A Line Calculator

Garment Industry Efficiency Formula

The following equation is used to calculate the Garment Industry Efficiency.

LE () = (O * GSAM) / (M*H*60) * 100

- Where LE is the line efficiency in the garment industry (%)

- O is the output of the line (# of pieces)

- GSAM is the standard minutes of a garment (machine SAM and manual SAM)

- M is the total manpower (#people)

- H is the shift hours (hours)

What is a Garment Industry Efficiency?

Definition:

In the garment industry, efficiency is most often used to describe line efficiency in a factory. This line efficiency measures how many garments the line produces relative to its theoretical maximum output.

How to Calculate Garment Industry Efficiency?

Example Problem:

The following example outlines the steps and information needed to calculate Garment Industry Efficiency.

First, determine the line output. In this example, the line output is 50 pieces.

Next, determine the Garment Sam. For this problem, the Garment SAM is 20 minutes.

Next, determine the manpower. For this example, 5 people are working on the line.

Next, determine the shift hours. Each worker is expected to work 8 hour shifts.

Finally, calculate the garment line efficiency using the formula above:

LE (%) = (O * GSAM) / (M*H*60) * 100

LE (%) = (50 * 20) / (5*8*60) * 100

LE (%) = 41.667 %