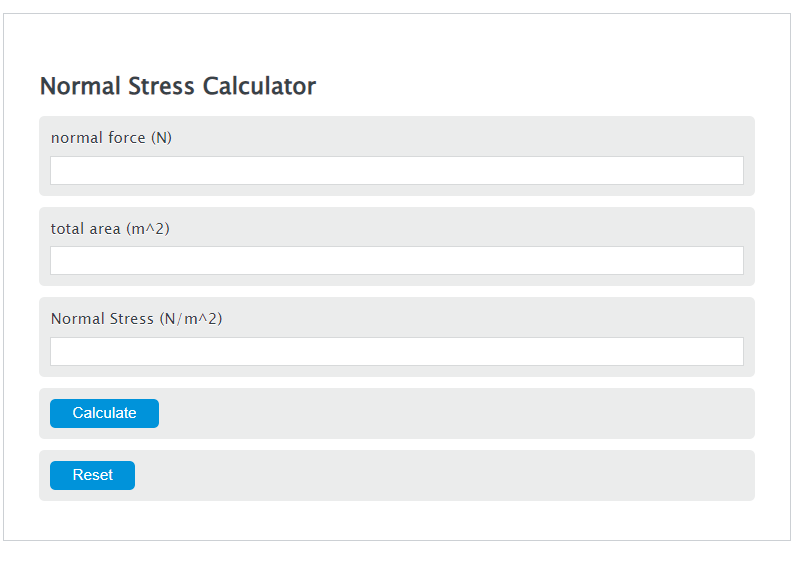

Enter the normal force (N) and the total area (m^2) into the Calculator. The calculator will evaluate the Normal Stress.

Normal Stress Formula

NS = NF / A

Variables:

- NS is the Normal Stress (N/m^2)

- NF is the normal force (N)

- A is the total area (m^2)

To calculate Normal Stress, divide the normal force by the area of contact.

How to Calculate Normal Stress?

The following steps outline how to calculate Normal Stress.

- First, determine the normal force (N).

- Next, determine the total area (m^2).

- Next, gather the formula from above = NS = NF / A.

- Finally, calculate the Normal Stress.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

normal force (N) = 507

total area (m^2) = 32

FAQs on Normal Stress

What is the significance of normal stress in engineering?

Normal stress plays a crucial role in engineering, particularly in the design and analysis of structures. It helps engineers determine whether a material or structure can withstand the forces acting upon it without failing. Understanding normal stress is essential for ensuring the safety and durability of buildings, bridges, and various mechanical components.

How does normal stress differ from shear stress?

Normal stress is the force per unit area acting perpendicular to the surface, whereas shear stress is the force per unit area acting parallel to the surface. Both types of stress are critical in the analysis of material strength, but they affect materials in different ways. Shear stress, for example, can cause materials to slide past one another, which is a different failure mode than that caused by normal stress.

Can normal stress be negative, and what does that indicate?

Yes, normal stress can be negative. This condition is known as tensile stress. Negative normal stress indicates that the material is under tension, meaning it is being pulled apart rather than compressed. This distinction is important in understanding how materials will behave under different loading conditions.

What are some common materials’ responses to normal stress?

Materials can respond to normal stress in various ways, including elastic deformation, plastic deformation, and failure. Elastic deformation is temporary and reversible, while plastic deformation is permanent. The failure point is when the material can no longer withstand the stress and breaks or fractures. The specific response depends on the material’s properties, such as its Young’s modulus, yield strength, and ultimate tensile strength.