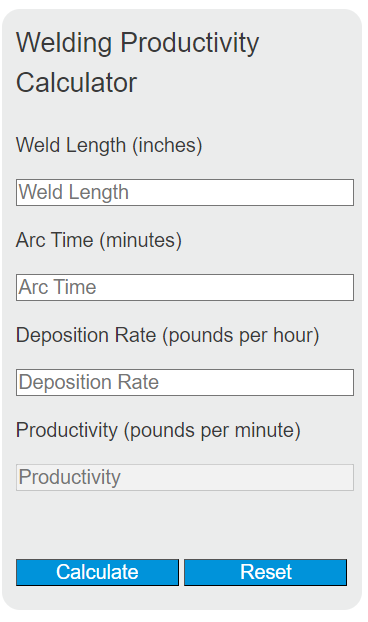

Enter the weld length, arc time, and deposition rate into the calculator to determine the welding productivity. This calculator helps in estimating the efficiency of the welding process.

Welding Productivity Formula

The following formula is used to calculate the welding productivity.

P = (L / A) * (D / 60)

Variables:

- P is the productivity (pounds per minute)

- L is the weld length (inches)

- A is the arc time (minutes)

- D is the deposition rate (pounds per hour)

To calculate the welding productivity, divide the weld length by the arc time to find the inches per minute, then multiply by the deposition rate converted to pounds per minute (deposition rate divided by 60).

What is Welding Productivity?

Welding productivity is a measure of the efficiency and speed of the welding process. It is calculated by considering the length of the weld completed in a given time frame and the rate at which welding material is deposited. This metric is crucial for project planning, cost estimation, and determining the overall efficiency of welding operations.

How to Calculate Welding Productivity?

The following steps outline how to calculate the Welding Productivity.

- First, determine the weld length (L) in inches.

- Next, determine the arc time (A) in minutes.

- Next, determine the deposition rate (D) in pounds per hour.

- Next, gather the formula from above = P = (L / A) * (D / 60).

- Finally, calculate the Welding Productivity (P) in pounds per minute.

- After inserting the variables and calculating the result, check your answer with the calculator above.

Example Problem :

Use the following variables as an example problem to test your knowledge.

Weld length (L) = 120 inches

Arc time (A) = 30 minutes

Deposition rate (D) = 6 pounds per hour