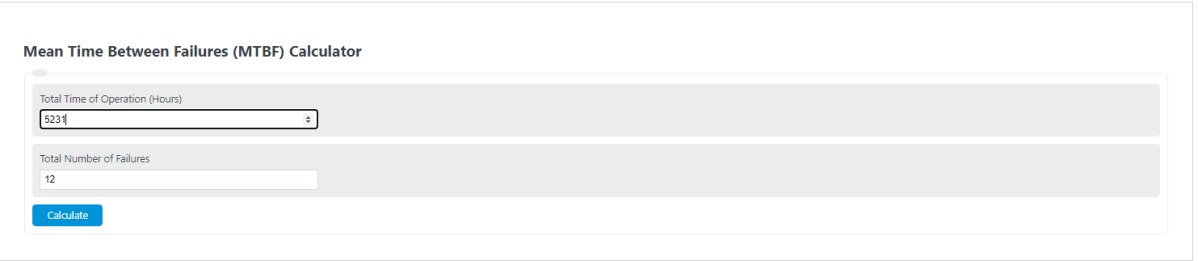

Enter the total operational time and the total number of failures into the calculator to determine the mean time between failures (MTBF).

- Mean Time To Failure (MTTF) Calculator

- Failure Rate Calculator

- DPMO Calculator (Defects Per Million Opportunities)

- Sigma Level Calculator

- Overall Equipment Effectiveness (OEE) Calculator

- MTR (Mean-Time-To-Repair) Calculator

MTBF Formula

The following formula is used to calculate the mean time between failures.

MTBF = TOT / TF

- Where MTBF is the mean time between failures

- TOT is the total operational time (hours)

- TF is the total number of failures

To calculate the mean time between failures, divide the total operational time by the total failures.

MTBF Definition

What is MTBF?

MTBF, short for mean time between failures, is a metric that describes the average time it takes to incur a failure on a piece of equipment.

The equipment can be manufacturing equipment that produces goods or something like air-conditioning.

Example Problem

How to calculate MTBF?

- First, determine the total hours of operation.

For this example, we are looking at an air-conditioning unit that has been running for a year straight. This is equal to 8760 hours of operation.

- Next, determine the total number of failures during the time period.

In this case, the air-conditioning failed a total of 5 times.

- Finally, calculate the MTBF.

Using the formula above the mean time between failures is calculated to be:

MTBF = TOT / TF

MTBF = 8760/5

MTBF = 1752 hours/failure

FAQ

What factors can affect the MTBF of a piece of equipment?

Several factors can affect the MTBF, including the quality of components used, the environment in which the equipment operates, maintenance practices, and the complexity of the equipment.

How can MTBF data be used to improve equipment reliability?

MTBF data can be used to identify trends and potential weaknesses in equipment. By analyzing this data, organizations can implement preventive maintenance strategies, choose higher-quality components, or redesign equipment for better reliability.

Is a higher MTBF always better?

While a higher MTBF indicates longer periods between failures, it is not always the sole indicator of better performance or reliability. It’s important to consider other factors such as the cost of downtime, the impact of failures, and the cost of achieving a higher MTBF.

Can MTBF be applied to non-physical systems, like software?

Yes, MTBF can also be applied to software systems to measure the time between failures. However, calculating MTBF for software can be more complex due to the different nature of software failures compared to physical equipment failures.