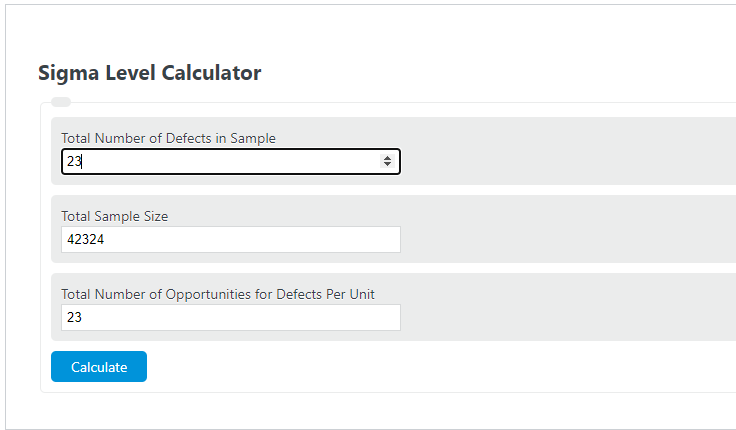

Enter the total number of defects found in a sample, the sample size, and the number of defect opportunities per item to calculate the sigma level.

- DPMO Calculator (Defects Per Million Opportunities)

- Rate Per 1000 Calculator

- CPK Calculator

- Ppk (Process Performance Index) Calculator

- System Reliability Calculator

- Defect Rate Calculator

Sigma Level Formula

The Sigma Level Formula is a statistical measure used to determine the quality and effectiveness of a process. It is computed by analyzing the number of defects or errors in a process relative to the number of opportunities for defects to occur.

The following table lists the sigma level on a defects per million basis and a percentage yield.

| Sigma Level | Defects Per Million DPMO | Yield % |

| 1 | 690,000 | 30.85% |

| 2 | 308,000 | 69.15% |

| 3 | 66,800 | 93.32% |

| 4 | 6,210 | 99.38% |

| 5 | 230 | 99.977% |

| 6 | 3.4 | 99.99966% |

Sigma Level Definition

What is sigma level? A sigma level is a term used in both statistics and manufacturing to describe the rate of defects per million opportunities as a function of the number of standard deviations from a mean of a sample. For example, in a standard mean data set of 1 million objects, only 3.4 out of a million would fall within the sixth standard deviation.

Sigma Level Example Problem

How to calculate sigma level?

- First, determine the total number of defects in the sample.

For this example, there were 100 defects found in the sample.

- Next, determine the sample size.

These defects were found in a sample size 5,000.

- Next, determine the number of opportunities for defects in each item.

There are 10 total possible spots of failure in the object.

- Next, calculate the DPMO.

Using the formula DPMO = Total defects / (sample size*opportunities for failure per item) * 1,000,000. This yields 2,000 DPMO.

- Finally, determine the sigma level.

Using the table above, the sigma level is found to be 4 sigmas.

About Sigma Level

What is a good sigma level? In manufacturing, the gold standard of quality is reaching a six sigma level. In fact, there are entire fields of study that go into reaching a six sigma quality level. However, lower sigma levels can be acceptable depending on the operation or product.

Can a sigma level be negative? No, sigma levels cannot be negative by definition. (At least in terms of manufacturing). The most possible failures are 100% failure or 0% yield. This would simply equate to a sigma level of 0.

How many sigma levels are there? There is an infinite number of possible sigma levels, but most studies only consider sigma levels of 1 through 6, with six being the highest sigma level.