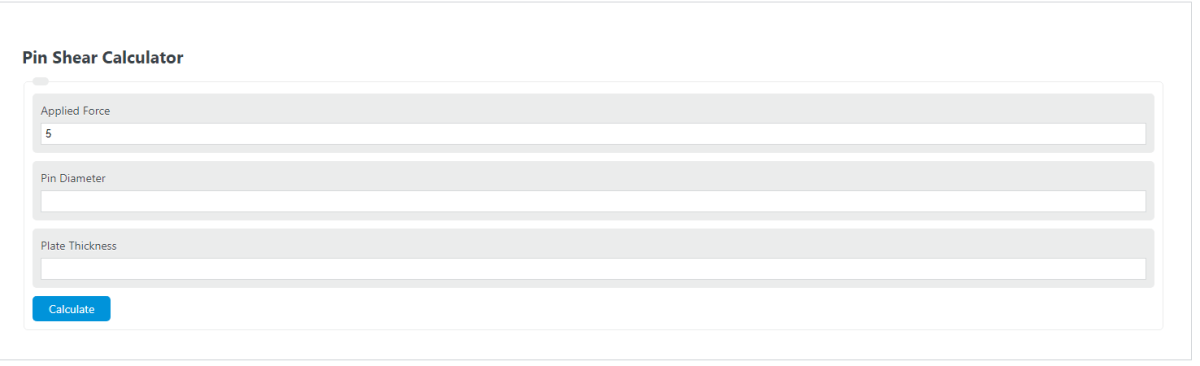

Enter the applied force, pin diameter, and plate thickness into the calculator to determine the pin shear stress and bearing area stress.

- Shear Strain Calculator

- Shear Stress Calculator

- Von Mises Stress Calculator

- Shear Modulus Calculator

- Flange Bolt Torque Calculator

- Shear Area Calculator

Pin Shear Formula

The following formula is used to calculate pin shear.

SS = 4*AF / (pi*D^2)

BS = AF / (t*d)

- Where SS is the pin shear stress (N/mm^2, lbs/in^2)

- BS is the bearing area stress (N/mm^2, lb/in^2)

- AF is the applied force (N, lbs)

- D is the diameter of the pin (mm , in)

- t is the thickness of the plate. (mm , in)

Pin Shear Definition

What is pin shear?

Pin shear is the average shear that a pin will see given an applied force and diameter. Pin shear is used to design safe bearing and other mechanical assemblies.

Typically the pin shear is used with the ultimate strength and factor of safety to determine the proper design setup.

However, since the pins can hold a large amount of shear stress relative to other components, they are rarely the limiting factor.

Example Problem

How to calculate average pin shear?

First, determine the applied force acting on the pin assembly. In this example, the applied force is measured to be 5000 N.

Next, determine the diameter of the pin. In this example, the pin is a diameter of 35mm.

Finally, calculate the pin shear using the formula above:

SS = 4*AF / (pi*D^2)

SS = 4*5000 / (3.14159*35^2)

SS = 5.196 N/mm^2

If you want to further calculate the total bearing area stress, determine the thickness of the plate, (in this case, 40mm), and use the formula above:

BS = AF / (t*d)

BS = 5000 / (35*40)

BS = 3.571 N/mm^2