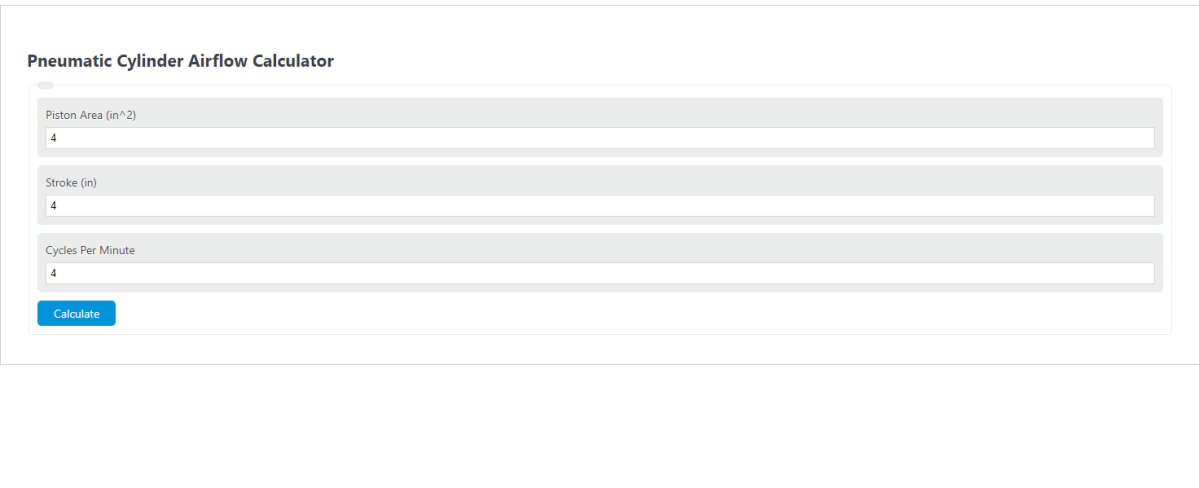

Enter the piston area, stroke, and cycles per minute into the calculator to determine the pneumatic cylinder airflow rate.

- Engine Mass Air Flow Calculator

- Air-Flow Calculator

- CFM Per Ton Calculator

- Air Exchange Calculator (Air Change Per Hour & Minute)

- Pneumatic Cylinder Velocity Calculator

Pneumatic Cylinder Airflow Formula

The following equation is used to calculate the Pneumatic Cylinder Airflow.

AF = (A*S*C) / 1728

- Where AF is the Pneumatic Cylinder Airflow (CFM = cubic feet per minute)

- A is the cross-sectional area of the piston (in^2)

- S is the stroke length (in)

- C is the cycles per minute

To calculate the pneumatic cylinder airflow, multiply the cross-sectional area by the stroke length and cycles per minute, then divide by 1728.

What is Pneumatic Cylinder Airflow?

Definition:

The airflow in a pneumatic cylinder system is the flow of air within a pneumatic system. Pneumatic cylinder systems are used in industrial and manufacturing processes to transfer force and motion from one location to another.

Gases such as air and nitrogen are compressed under pressure by a compressor then sent through a series of valves and cylinders to perform the desired task.

Three different methods can create pneumatic cylinder airflow: unbalanced, balanced, and constant-flow.

Unbalanced airflow occurs when there is no means of controlling gas flow speed through a pneumatic cylinder.

Balanced airflow occurs when the air supply determines the maximum pressure that can be used, but it is also possible to vary the pressure or volume of air being supplied to each cylinder.

Constant-flow airflow occurs when a constant air volume or pressure is maintained by a regulator downstream from an air pump, which controls the compressed air from entering the system.

FAQ

What factors affect the efficiency of a pneumatic cylinder system?

The efficiency of a pneumatic cylinder system can be influenced by several factors including the quality of the compressed air (presence of moisture or impurities), the type of valves used (whether they are properly sized and functioning), the design of the system (including the layout of pipes and cylinders), and how well the system is maintained.

How can you increase the airflow in a pneumatic cylinder system?

To increase airflow in a pneumatic cylinder system, you can increase the compressor’s pressure setting, use larger diameter pipes or hoses to reduce resistance, ensure that the air is dry and clean to avoid blockages, and use more efficient valves and fittings that minimize air leakage and resistance.

What is the significance of the formula AF = (A*S*C) / 1728 in calculating pneumatic cylinder airflow?

The formula AF = (A*S*C) / 1728 is significant because it provides a direct method to calculate the airflow in cubic feet per minute (CFM) required by a pneumatic cylinder to operate based on its dimensions and the frequency of its cycles. This calculation is crucial for designing or optimizing pneumatic systems to ensure they have adequate airflow to perform their intended functions efficiently.