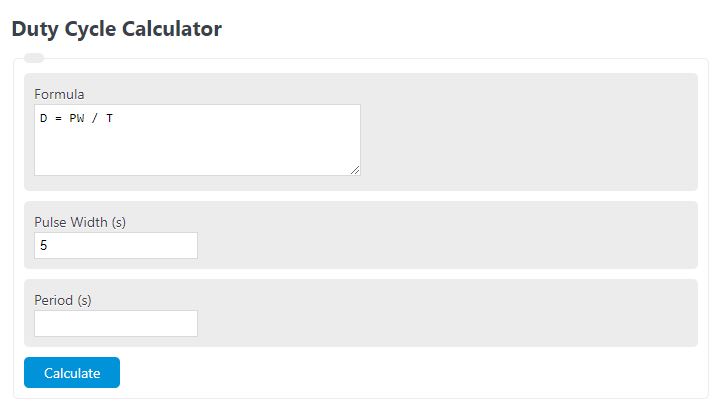

Enter the pulse width and the period into the calculator to determine the duty cycle. This calculator can also evaluate the pulse width or period when the other variables are known.

- All Electrical Calculators

- Cutoff Frequency Calculator

- Natural Frequency Calculator

- Takt Time Calculator

- Injector Duty Cycle Calculator

- RF Average Power to Peak Power Calculator

- Pulsed Laser Average Power Calculator

- PWM to Voltage Calculator

- Process Cycle Time Reduction Calculator

Duty Cycle Formula

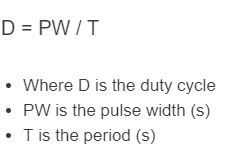

The following formula is used to calculate a duty cycle.

D = PW / T

- Where D is the duty cycle

- PW is the pulse width (s)

- T is the period (s)

To calculate a duty cycle, divide the pulse width by the period length.

Duty Cycle Definition

A duty cycle is defined as the ratio of the pulse width to the period of a transmitter and is a measure of the time that the transmitter is emitting a signal.

Duty Cycle Example

How to calculate duty cycle?

- First, determine the pulse width.

For this example, we will say the pulse width is .03 seconds.

- Next, determine the period.

For this example, we will assume the period is .05 seconds.

- Finally, calculate the duty cycle.

Using the formula above we find the duty cycle is: .03/.05 = .60 = 60%.

5 Things to Know About Duty Cycle

What is a 50% duty cycle?

A 50% duty cycle represents a system in which the on-time and the off-time are equal. In other words, the minimum and maximum “states” of the system are equally present.

What is a 100% duty cycle?

A 100% duty cycle represents a system in which it is always in a state of “on” or full power. This means the system never turns off, or the power supplied never stops.

What is a duty cycle measurement?

A duty cycle measurement is a process of determining the percentage of time a system spends in the “on” state. This measurement is usually done using volt-meters and measuring the voltage delivered to the system over time.

Is the duty cycle the same as pulse width?

A duty cycle is the reciprocal of the pulse width. The pulse width is the percentage of time spent in the off position while a duty cycle is the percentage of time spent on the on position.

What is a 30-minute duty cycle?

A 30-minute duty cycle means that the total time to cycle through both the on and off positions is 30 minutes.

What Is the Difference Between Duty Cycle and Frequency?

While the duty cycle is the percentage of time that the signal is one, the frequency is how often a signal switches between high and low states, and it is expressed in Hz. So when the signal is high, it is considered on time, and the duty cycle tells you how much of one cycle it spends on. The frequency is different because it measures how many times the signal switches during the cycle.

Are PWM and Duty Cycle the Same?

PWM stands for pulse width modulation. It is a way to control analog devices with digital output. This is how they take dimmable lights, speakers, and other analog devices and give digital output to them. What PMW does is simulate an analog result by sending power in pulses, which are short bursts of regulated voltage.

Can Digital Oscilloscopes Measure Duty Cycle?

A digital oscilloscope is a diagnostic instrument, and it can draw a graph of an electrical signal. This graph can tell you different information about the signal, such as the time and voltage values of the cycle, its frequency, and changes over time. One of the benefits is that it can accurately reconstruct a signal. It can measure the pulse waves for communications equipment, x-rays, and radar.

The duty cycle lets you know the period that you can run a system at a high amperage. If you have a welding machine, and it has a 30% duty cycle at 200 amps. This means that for 10 minutes, you can maintain 200 amps for three. The rest of the time, it cools down by switching to thermal overload.

This is important because electrical systems heat up when they are at higher amps. Each type of system has a different ability, which is why the duty cycle is important. This way, you know what the device is capable of doing.

What Is the Formula for Duty Cycle?

The formula for duty cycle is as follows: D = PW/T

In this formula, D is the duty cycle, PW is the pulse width or the pulse active time, and T is the time period of the cycle.

Final Words

There are different types of duty cycles. The first is continuous duty, which is where the machine can run for an extended period of time before it reaches its thermal equilibrium. The short time duty is the number of minutes in the duty cycle that the device operates. Finally, the periodic duty is all of the duty cycles, and it focuses on starting, electric braking, and swapping loads.