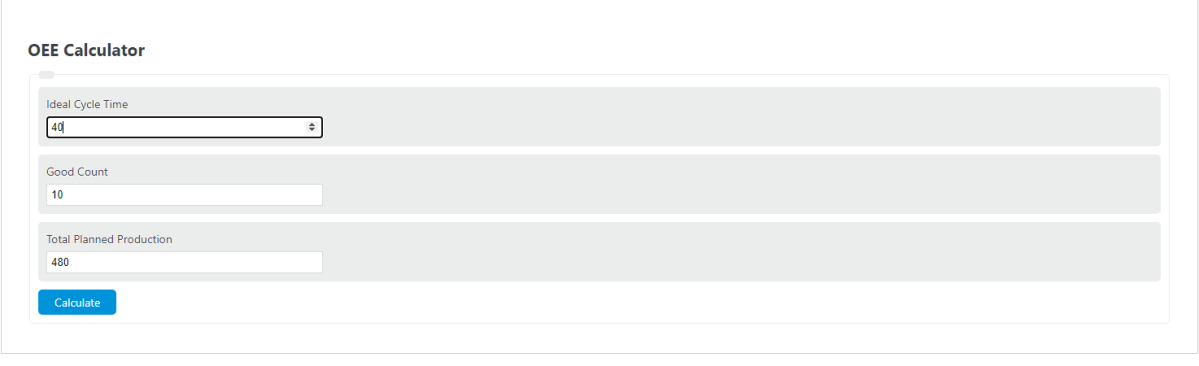

Enter the total good count, the ideal cycle time, and the total planned produced time to determine the overall equipment effectiveness (OEE).

- Total Manufacturing Cost Calculator

- Manufacturing Overhead Calculator

- Mean Time To Failure (MTTF) Calculator

- Mean Time Between Failures (MTBF) Calculator

- Ball Screw Life Calculator

OEE Formula

The following formula is used to calculate the overall effectiveness of equipment.

OEE= IDCT * GC / PPT

- Where OEE is the overall equipment effectiveness

- IDCT is the ideal cycle time (min/hours)

- GC is the good count or number of produced pieces that satisfy set requirements.

- PPT is the planned production time (min/hours)

It’s important that both the ideal cycle time and planned production time are entered with the same units of time into the calculator or formula.

OEE Definition

What is OEE?

OEE, short for overall equipment effectiveness, is a metric used in manufacturing to analyze the theoretical total output of a piece of equipment.

Example Problem

How to calculate OEE?

- First, determine the ideal cycle time.

For this example, the idea cycle time is found to be 40 minutes.

- Next, determine the good count.

In this case, 10 pieces are required to meet the requirement.

- Next, determine the total planned production time.

For this problem, the total planned production time is 480 minutes.

- Finally, calculate the overall equipment effectiveness.

Using the formula above, the OEE is calculated to be:

OEE= IDCT * GC / PPT

OEE= 40 * 10 / 480

OEE= .8333

FAQ

What factors can affect the OEE score?

OEE scores can be affected by several factors including machine breakdowns, setup and adjustment time, idling and minor stoppages, reduced speed, process defects, and reduced yield. Each of these factors can decrease the effective operational time, the speed of production, and the quality of the output, thus lowering the OEE score.

How can OEE be improved in a manufacturing setting?

Improving OEE requires a comprehensive approach that includes regular equipment maintenance to reduce breakdowns, optimizing production processes to minimize downtime and defects, training employees to enhance operational efficiency, and implementing quality control measures to increase the good count. Continuous monitoring and analysis of OEE data also help in identifying areas for improvement.

Why is it important to measure OEE in manufacturing?

Measuring OEE is crucial in manufacturing because it provides a clear and quantifiable measure of how effectively a manufacturing operation is utilizing its resources. By highlighting areas of waste and inefficiency, OEE helps manufacturers identify opportunities for improvement, ultimately leading to cost savings, higher quality products, and increased production capacity.