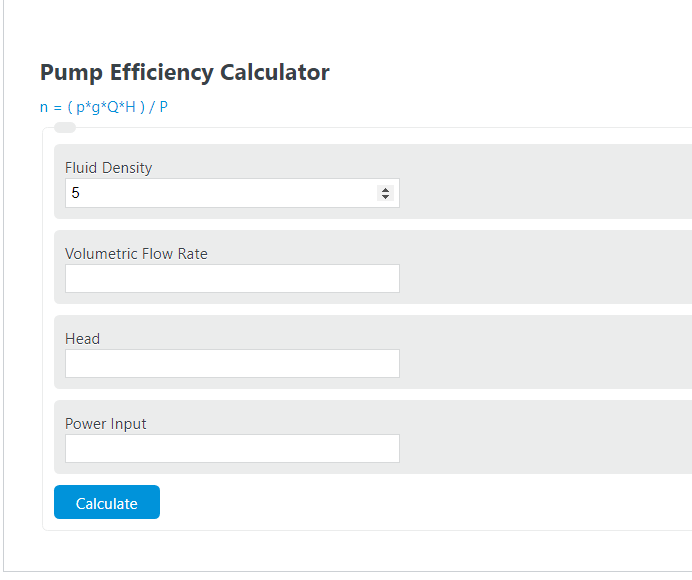

Enter the density of the fluid, flow rate, head, and power input into the calculator to determine the pump efficiency.

- Brake Horsepower Calculator

- Volumetric Flow Rate Calculator

- Water Flow Rate Calculator

- NPSHA Calculator

- Tip Speed Calculator

- Pump Shaft Power Calculator

- Reciprocating Compressor Volumetric Efficiency Calculator

Pump Efficiency Formula

The following formula is used to calculate pump efficiency.

n = ( p*g*Q*H ) / P

- Where n is the efficiency

- p is the density of the fluid being moved by the pump

- g is the gravitational constant

- Q is the flow rate

- H is the head

- P is the power input

This formula can further be simplified to power output divided by power input. This is the case because the power output of a pump is calculated using the numerator of the equation above.

To calculate the pump efficiency, multiply the density, gravitational constant, flow rate, and head together, then divide by the power input.

Example Problem

How to calculate pump efficiency?

To calculate pump efficiency, you first need to determine the variables presented in the equation above. The first of which is the density of the fluid. For this example, we will assume the fluid is water and has a density of 997 kg/m^3.

Next, determine the flow rate of the pump. Using either published data, or experimental data, we find the pump volumetric flow rate to be 20 m^3/s.

Next, the head is calculated to be 5m.

Next, calculate the power input. This is the power that the pump consumes for operation. For this problem, the pump consumes 50 W of power.

Finally, using all of the values above, the pump efficiency can be calculated using the equation: ( p*g*Q*H ) / P

So, (997*6.647*10^-11*11 * 20) / 50

= .000000291

= .0000291%

FAQ

What factors can affect pump efficiency?

Pump efficiency can be affected by several factors including the design of the pump, the condition of the pump (wear and tear), the type of fluid being pumped, the viscosity of the fluid, and how well the pump is matched to the system it’s being used in. Improper installation or maintenance can also significantly impact efficiency.

How can you improve the efficiency of a pump?

Improving pump efficiency can be achieved through regular maintenance, ensuring the pump is correctly sized for its application, using speed controls to adjust the flow rate as needed, minimizing the flow resistance in the system by installing the correct piping, and replacing worn components. Additionally, selecting a pump design that is best suited for the specific fluid and application can greatly improve efficiency.

Why is calculating pump efficiency important?

Calculating pump efficiency is important for several reasons. It helps in determining the cost-effectiveness of the pump operation, ensuring that the pump is operating as intended, and identifying potential areas for improvement. Understanding pump efficiency can also aid in the selection of the most suitable pump for a specific application, thereby reducing energy consumption and operational costs.