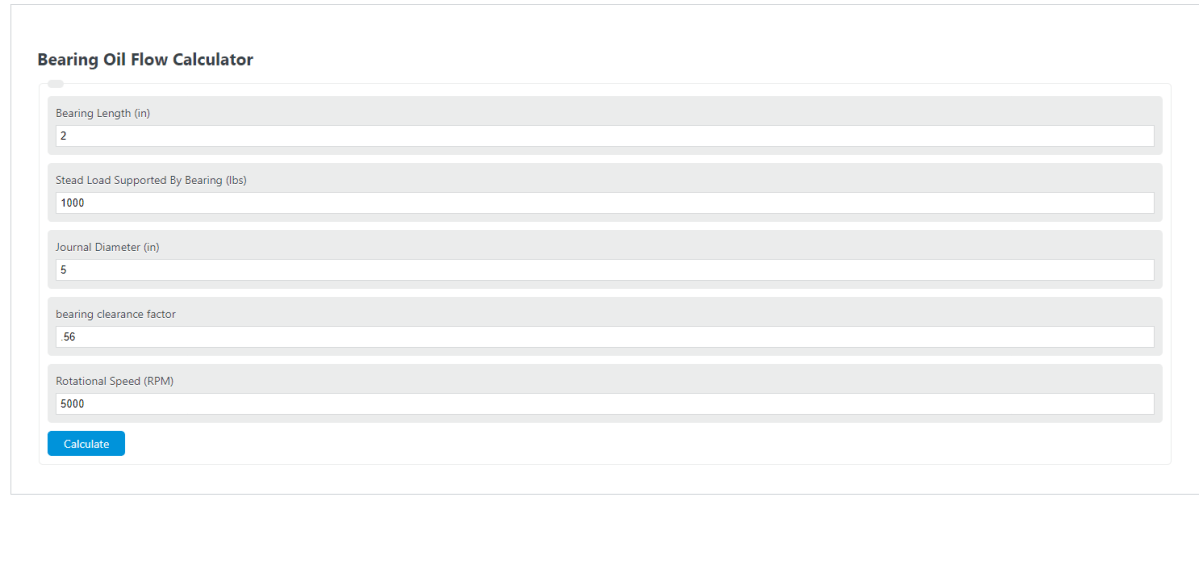

Enter the journal diameter, bearing length, bearing clearance factor, rotational speed, and supported load to determine the bearing oil flow.

Bearing Oil Flow Formula

The following equation is used to calculate the Bearing Oil Flow.

Q = 29.3*10^-9*(L+.0043(W/D))*m*D^2*N

- Where Q is the bearing oil flow (gallons per minute)

- L is the bearing length (inches)

- W is the stead load supported by the bearing (lbs)

- D is the diameter of the journal (inches)

- m is the bearing clearance factor

- N is the rotational speed (RPM)

What is Bearing Oil Flow?

Definition:

Bearing oil flow is the amount of oil that can pass through the bearings of a machine. The oil, which is used to lubricate and cool the surface of the bearings, must be able to pass through the bearings in order for it to have any effect on them.

FAQ

What factors influence the bearing oil flow rate?

Several factors can influence the bearing oil flow rate, including the diameter of the journal, the length of the bearing, the bearing clearance factor, the rotational speed of the bearing, and the load supported by the bearing. Environmental factors, such as temperature and pressure, as well as the viscosity of the oil, also play a critical role in determining the flow rate.

How can incorrect bearing oil flow affect machine performance?

Incorrect bearing oil flow can lead to several problems, including insufficient lubrication, overheating, increased wear and tear, and ultimately, bearing failure. Too little oil flow can result in inadequate lubrication and cooling, while too much oil flow can cause energy loss and contamination of the bearing environment. Both scenarios can significantly reduce the lifespan of the bearing and affect the overall efficiency and reliability of the machine.

What are some methods for measuring and adjusting bearing oil flow?

Bearing oil flow can be measured using oil flow gauges or sensors that monitor the rate at which oil passes through the bearing. Adjustments to the oil flow can be made by changing the oil viscosity, adjusting the clearance between the bearing and the journal, modifying the oil supply pressure, or altering the design of the lubrication system. Regular monitoring and maintenance are essential to ensure optimal bearing performance and to prevent potential issues related to incorrect oil flow.