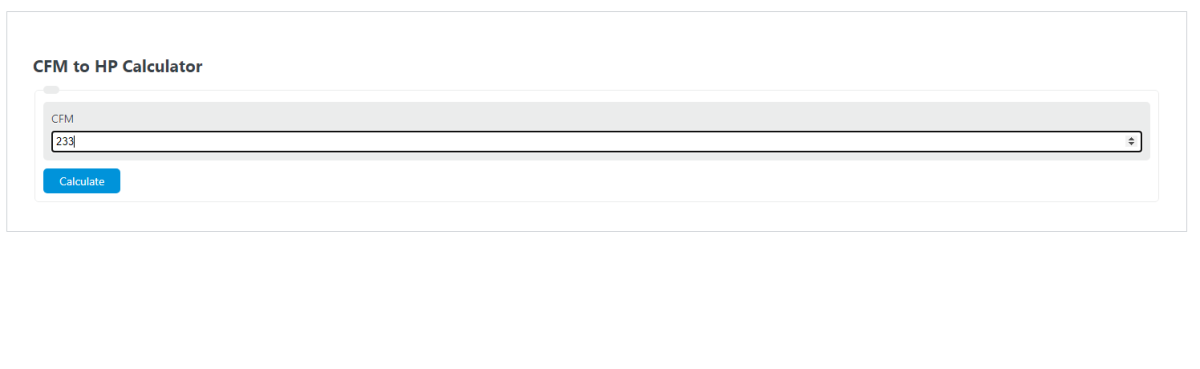

Enter the total amount of airflow in cubic feet per minute (CFM) into the calculator to estimate the horsepower of the motor.

- CC to HP Calculator

- HP to Torque Calculator

- Boost to HP Calculator

- Horsepower Quarter Mile Calculator

- Hydraulic Motor Flow Calculator

- Engine Intake Diameter Calculator

CFM To HP Formula

The following formula is used to estimate or convert CFM to HP.

HP = (CFM * 1.44)

- Where HP is the total horsepower

- CFM is the airflow in cubic feet per minute

CFM to HP Definition

How is CFM converted into HP?

CFM can be converted into HP by multiplying the airflow by 1.6 and multiplying that result by 0.9.

Example Problem

How to calculate HP from CFM?

The following example problem outlines the steps and information that are needed to estimate the total amount of horsepower an engine has based on its airflow intake in cubic feet per minute.

First, determine the total amount of air intake of the engine. For this example problem, the air intake is at a rate of 500 CFM.

Next, use the formula above to estimate the horsepower:

HP = (CFM * 1.44)

HP = (500 * 1.44)

HP = 720 horsepower

FAQ

What is the relationship between CFM and HP in air compression systems?

The relationship between CFM (cubic feet per minute) and HP (horsepower) in air compression systems is directly proportional. A higher HP rating of a compressor means it can produce a higher CFM of air.

How does velocity affect the flow rate in an air compressor?

Velocity affects the flow rate in an air compressor by changing the speed of the air as it moves through the compressor. A higher air velocity will result in a higher flow rate, while a lower velocity will result in a lower flow rate.

What is the difference between PSI and CFM in air compression systems?

PSI (pounds per square inch) and CFM (cubic feet per minute) are two different units of measurement used in air compression systems. PSI is used to measure the pressure of the air, while CFM is used to measure the flow rate of the air.

How does the size of an air compressor affect its CFM and HP ratings?

The size of an air compressor affects its CFM and HP ratings in that a larger compressor will typically have a higher CFM and HP rating than a smaller compressor. This is because a larger compressor has more space for the air to be compressed, resulting in a higher flow rate.

How is CFM calculated in air compression systems?

CFM is calculated in air compression systems by multiplying the cross-sectional area of the air outlet by the velocity of the air as it exits the compressor. This value represents the volume of air that is being compressed and moved through the system per minute.

What is the relationship between CFM and velocity in air compression systems?

The relationship between CFM and velocity in air compression systems is directly proportional. As the velocity of the air increases, the CFM of the air also increases. A higher velocity results in a larger air volume being compressed and moved through the system.

How does pressure affect the CFM and HP ratings of an air compressor?

Pressure affects the CFM and HP ratings of an air compressor by changing the work the compressor has to do. A higher pressure will result in a higher CFM and HP rating, while a lower pressure will result in a lower CFM and HP rating.

What is the relationship between CFM and air consumption in air tools?

The relationship between CFM and air consumption in air tools is directly proportional. A higher CFM rating of an air compressor means it can supply more air to the air tools, resulting in higher air consumption.

How does the type of air compressor affect its CFM and HP ratings?

The type of air compressor affects its CFM and HP ratings based on the design and operating principle of the compressor. For example, a reciprocating compressor will typically have a lower CFM and HP rating compared to a rotary screw compressor, which is designed for higher flow rates.

How does the flow rate of an air compressor affect the performance of air tools?

The flow rate of an air compressor affects the performance of air tools by providing a steady supply of air to the tools. A higher flow rate results in a higher performance of the air tools, while a lower flow rate results in lower performance. The CFM rating of the air compressor is an indicator of its flow rate and ability to supply air to the air tools.