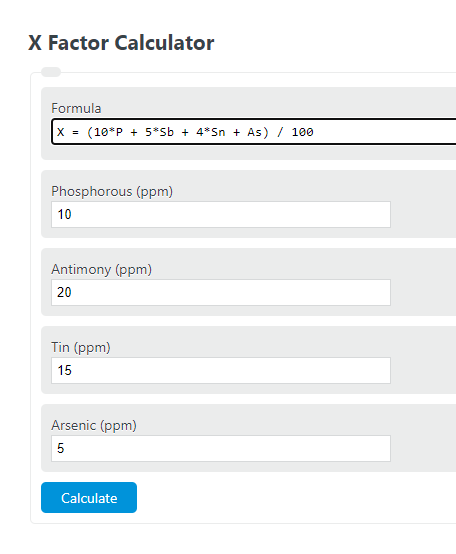

Enter the ppm of phosphorous, antimony, tin, and arsenic of the filler metal into the calculator to determine the x-factor.

- Von Mises Stress Calculator

- PPM Calculator

- Brinell Hardness Number Calculator w/ Formula

- Heat Input Calculator

- Welding Machine Load Calculator

- Welding Machine Amperage Calculator

- Weld Force Calculator

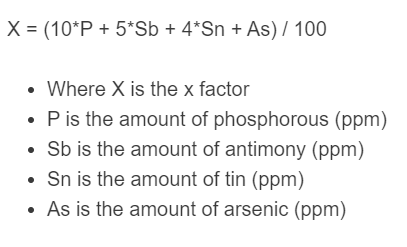

X Factor Formula

The following formula is used to calculate an X factor for welding.

X = (10*P + 5*Sb + 4*Sn + As) / 100

- Where X is the x-factor

- P is the amount of phosphorous (ppm)

- Sb is the amount of antimony (ppm)

- Sn is the amount of tin (ppm)

- As is the amount of arsenic (ppm)

To calculate the X factor, multiply the amount phosphorous by 10, amount of antimony by 5, amount of tin by 4, add the results together along with the amount of arsenic, then divide by 100.

X Factor Definition

What is an x-factor for welding? An x-factor is a term used in welding to describe the metal filler or weldment’s resistance to brittleness or loss of toughness when the weldment is held.

Example Problem

How to calculate an X factor?

- First, determine the amount of phosphorous.

For this example, there is 10 ppm of phosphorous.

- Next, determine the amount of antimony.

For this example, there is 20 ppm of antimony.

- Next, determine the amount of tin.

For this problem, there is 15 ppm of tin.

- Next, determine the amount of arsenic.

For this example, there is 5 ppm of arsenic.

- Finally, calculate the x factor.

Using the formula, X = (10*10 + 20*5 + 15*4 + 5) / 100 = 2.65

FAQ

What is the significance of the X factor in welding?

The X factor in welding is significant because it helps in assessing the filler metal’s susceptibility to cracking and brittleness, especially in high-stress environments. A lower X factor indicates a lower likelihood of brittleness, making it a critical parameter for ensuring the durability and integrity of welded structures.

How can the ppm of elements like phosphorous, antimony, tin, and arsenic affect the welding process?

The parts per million (ppm) of elements such as phosphorous, antimony, tin, and arsenic in filler metals can significantly affect the welding process by altering the metal’s mechanical properties. High levels of these elements can increase the risk of cracking and brittleness in the weld area, affecting the overall strength and durability of the welded joint.

Are there any other factors that should be considered when calculating the X factor for welding?

Yes, besides the ppm of phosphorous, antimony, tin, and arsenic, other factors such as the base metal composition, welding technique, and cooling rate can also influence the X factor and the overall quality of the weld. Understanding the comprehensive interaction of these variables is crucial for optimizing welding parameters and achieving desired outcomes.