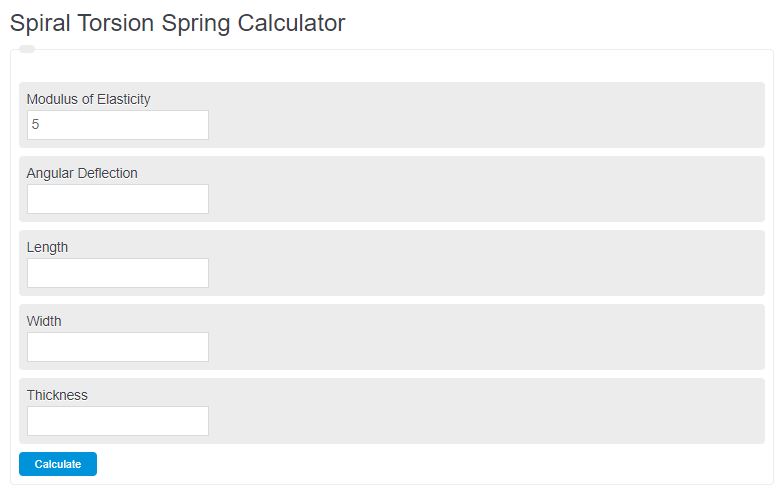

Enter the modulus of elasticity, angular deflection, length, width, and thickness of a torsion spring into the calculator to determine the torque.

- Torque Calculator

- Elasticity Calculator (Physics)

- Angular Momentum Calculator

- Young’s Modulus Calculator

- Torsion Constant Calculator

- Spring Wire Length Calculator

- Rubber Deflection Calculator

- Spiral Length Calculator

- Gas Spring Force Calculator

- Torsion Bar Spring Energy Calculator

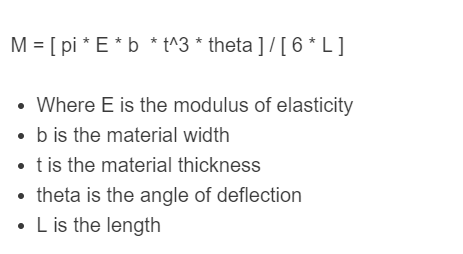

Spiral Torsion Spring Formula

The following formula is used to calculate the torque provided by a spiral spring.

M = [ pi * E * b * t^3 * theta ] / [ 6 * L ]

- Where E is the modulus of elasticity

- b is the material width

- t is the material thickness

- theta is the angle of deflection

- L is the length

Spiral Torsion Definition

Spiral torsion is the measure of torque of the moment about an axis caused by a helical spring and twisting force.

Spiral Torsion Example

How to calculate spiral torsion?

- First, determine the modulus of elasticity.

Calculate the modulus of elasticity.

- Next, determine the material width.

Measure the width of the material.

- Next, determine the thickness of the material.

Measure the total thickness.

- Next, determine the length.

Calculate the total length of the spring.

- Finally, calculate the spiral torsion.

Calculate the spiral torsion using the equation above.

FAQ

What factors affect the torque provided by a spiral torsion spring?The torque provided by a spiral torsion spring is affected by the modulus of elasticity, the material width, the material thickness, the angle of deflection, and the length of the spring.

How can you increase the torque of a spiral torsion spring?To increase the torque of a spiral torsion spring, you can increase the modulus of elasticity, the material width, or the material thickness. Alternatively, increasing the angle of deflection or decreasing the length of the spring can also increase torque.

What applications utilize spiral torsion springs?Spiral torsion springs are commonly used in applications requiring rotational force or torque, such as clocks, watches, industrial machinery, and various types of automotive components.