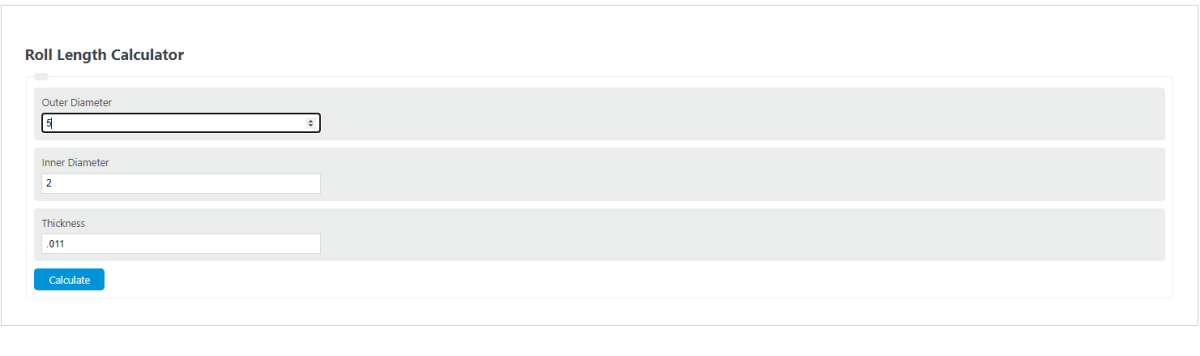

Enter the inner diameter, outer diameter, and thickness into the calculator to determine the length of the roll of material.

- MSI Calculator

- GSM (Grams Per Square Meter) Calculator

- Outside Diameter of a Roll Calculator

- Paper Weight Conversion Calculator

- Bias Tape/Binding Calculator

- Plate Thickness Calculator

- Steps Per MM Calculator

- Roll Crusher Capacity Calculator

- Paper Reel Weight Calculator

Roll Length Formula

The following formula is used to calculate the length of a roll of material.

L = pi * (OD^2/4 - ID^2/4) / t

- Where L is the roll length

- OD is the outer diameter

- ID is the inner diameter

- t is the thickness

A roll length is calculated by multiplying the difference between the diameters squared over 4, by pi, then dividing by the thickness.

Roll Length Definition

A roll length is defined as the length of a material that has been rolled into a cylindrical form with a given material thickness.

Example Problem

How to calculate roll length?

First, determine the outer diameter. For this problem, we are looking at a roll of duct tape that has an outer diameter of 5 inches.

Next, determine the inner diameter. For this example, the duct tape has an inner diameter of 2 inches.

Next, determine the material thickness. On average, duct tape has a thickness of .011 inches, so that will be used.

Finally, use the formula to calculate the roll length:

L = pi * (OD^2/4 – ID^2/4) / t

= 3.14159 *(5^2/4 – 2^2/4)/.011

= 1499.39 inches.